As of early 2026, the global semiconductor industry has officially shed its reputation for cyclical volatility, evolving into the foundational "sovereign infrastructure" of the modern world. Driven by an insatiable demand for generative AI and the rapid industrialization of intelligence, the sector is now on a confirmed trajectory to surpass $1 trillion in annual revenue by 2030. This shift represents a historic pivot where silicon is no longer just a component in a device, but the very engine of a new global "Token Economy."

The immediate significance of this milestone cannot be overstated. Analysts from McKinsey & Company and Gartner have noted that the industry’s growth is being propelled by a fundamental transformation in how compute is valued. We have moved beyond the era of simple hardware sales into a "Silicon Supercycle," where the ability to generate and process AI tokens at scale has become the primary metric of economic productivity. With global chip revenue expected to reach approximately $733 billion by the end of this year, the path to the trillion-dollar mark is paved with massive capital investments and a radical restructuring of the global supply chain.

The Rise of the Token Economy and the 2nm Frontier

Technically, the drive toward $1 trillion is being fueled by a shift from raw FLOPS (floating-point operations per second) to "tokens per second per watt." In this emerging "Token Economy," a token—the basic unit of text or data processed by an AI—is treated as the new "unit of thought." This has forced chipmakers to move beyond general-purpose computing toward highly specialized architectures. At the forefront of this transition is NVIDIA (NASDAQ: NVDA), which recently unveiled its Rubin architecture at CES 2026. This platform, succeeding the Blackwell series, integrates HBM4 memory and the new "Vera" CPU, specifically designed to reduce the cost per AI token by an order of magnitude, making massive-scale reasoning models economically viable for the first time.

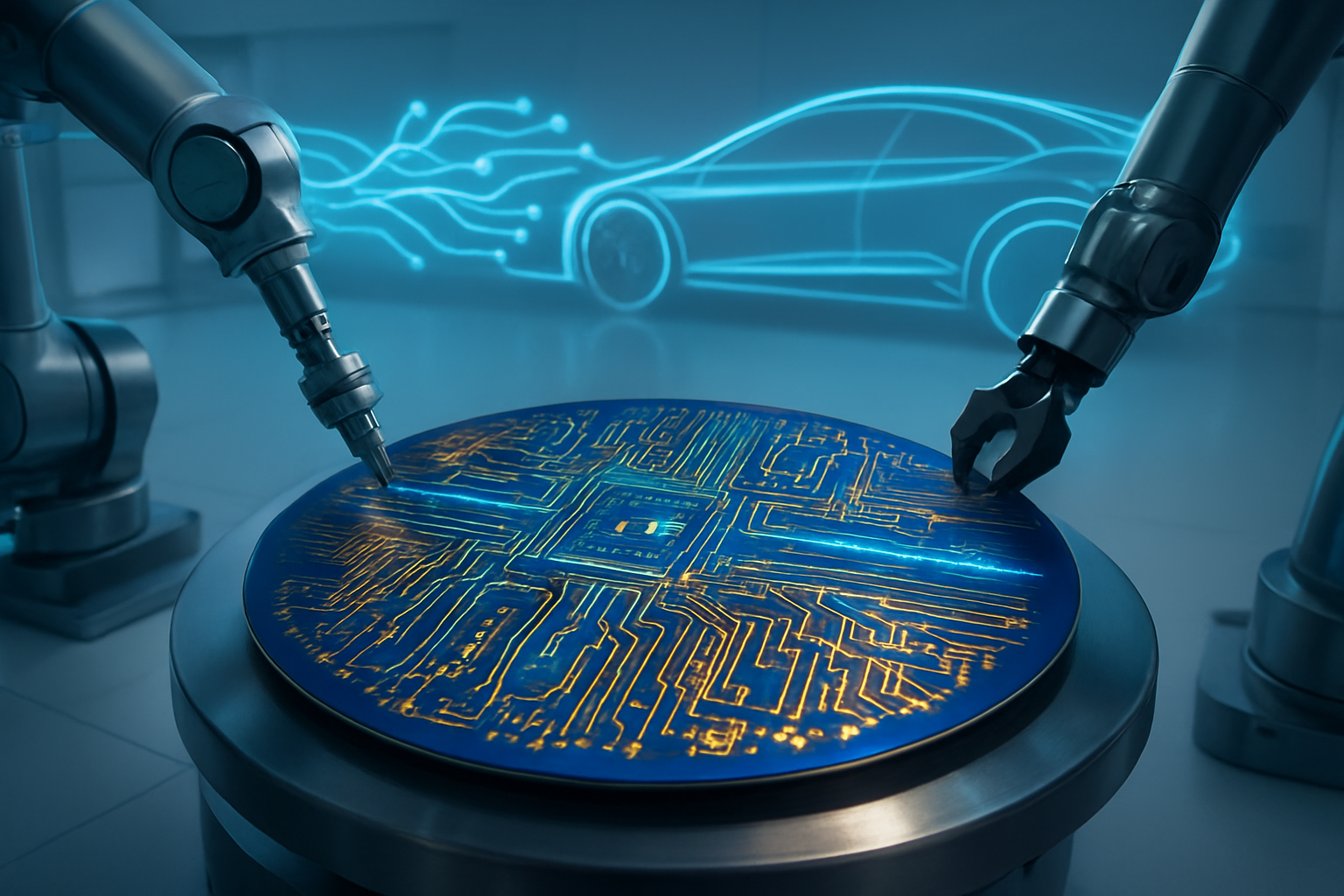

The technical specifications of this new era are staggering. To support the Token Economy, the industry is racing toward the 2nm production node. TSMC (NYSE: TSM) has already begun high-volume manufacturing of its N2 process at its fabs in Taiwan, with capacity reportedly booked through 2027. This transition is not merely about shrinking transistors; it involves advanced packaging technologies like CoWoS (Chip-on-Wafer-on-Substrate), which allow for the fusion of logic, HBM4 memory, and high-speed I/O into a single "chiplet" complex. This architectural shift is what enables the massive memory bandwidth required for real-time AI inference at the edge and in the data center.

Initial reactions from the AI research community suggest that these hardware advancements are finally closing the gap between model potential and physical reality. Experts argue that the ability to perform complex multi-step reasoning on-device, facilitated by these high-efficiency chips, will be the catalyst for the next wave of autonomous AI agents. Unlike previous cycles that focused on mobile or PC refreshes, this supercycle is driven by the "industrialization of intelligence," where every kilowatt of power is optimized for the highest possible token output.

Strategic Realignment: From Chipmakers to AI Factory Architects

The march toward $1 trillion is fundamentally altering the competitive landscape, benefiting those who can provide "full-stack" solutions. NVIDIA (NASDAQ: NVDA) has successfully transitioned from a GPU provider to an "AI Factory" architect, selling entire pre-integrated rack-scale systems like the NVL72. This model has forced competitors to adapt. Intel (NASDAQ: INTC), for instance, has pivoted its strategy toward its "18A" (1.8nm) node, positioning itself as a primary Western foundry for bespoke AI silicon. By focusing on its "Systems Foundry" approach, Intel is attempting to capture value not just from its own chips, but by manufacturing custom ASICs for hyperscalers like Amazon and Google.

This shift has profound implications for major AI labs and tech giants. Companies are increasingly moving away from off-the-shelf hardware in favor of vertically integrated, application-specific integrated circuits (ASICs). AMD (NASDAQ: AMD) has gained significant ground with its MI325 series, offering a competitive alternative for inference-heavy workloads, while Samsung (KRX: 005930) has leveraged its lead in HBM4 production to secure massive orders for AI-centric memory. The strategic advantage has moved to those who can manage the "yield war" in advanced packaging, as the bottleneck for AI infrastructure has shifted from wafer starts to the complex assembly of multi-die systems.

The market positioning of these companies is no longer just about market share in PCs or smartphones; it is about who owns the "compute stack" for the global economy. This has led to a disruption of traditional product cycles, with major players now releasing new architectures annually rather than every two years. The competitive pressure is also driving a surge in M&A activity, as firms scramble to acquire specialized networking and interconnect technology to prevent data bottlenecks in massive GPU clusters.

The Global Fab Build-out and Sovereign AI

The wider significance of this $1 trillion trajectory is rooted in the "Sovereign AI" movement. Nations are now treating semiconductor manufacturing and AI compute capacity as vital national infrastructure, similar to energy or water. This has triggered an unprecedented global fab build-out. According to SEMI, nearly 100 new high-volume fabs are expected to be online by 2027, supported by government initiatives like the U.S. CHIPS Act and similar programs in the EU, Japan, and India. These facilities are not just about capacity; they are about geographic resilience and the "de-risking" of the global supply chain.

This trend fits into a broader landscape where the value is shifting from the hardware itself to the application-level value it generates. In the current AI supercycle, the real revenue is being made at the "inference" layer—where models are actually used to solve problems, drive cars, or manage supply chains. This has led to a "de-commoditization" of silicon, where the specific capabilities of a chip (such as its ability to handle "sparsity" in neural networks) directly dictate the profitability of the AI service it supports.

However, this rapid expansion also brings significant concerns. The energy consumption of these massive AI data centers is a growing point of friction, leading to a surge in demand for power-efficient chips and specialized cooling technologies. Furthermore, the geopolitical tension surrounding the "2nm race" continues to be a primary risk factor for the industry. Comparisons to previous milestones, such as the rise of the internet or the mobile revolution, suggest that while the growth is real, the consolidation of power among a few "foundry and AI titans" could create new systemic risks for the global economy.

Looking Ahead: Quantum, Photonics, and the 2030 Goal

Looking toward the 2030 horizon, the industry is expected to face both physical and economic limits that will necessitate further innovation. As we approach the "end" of traditional Moore's Law scaling, researchers are already looking toward silicon photonics and 3D stacked logic to maintain the necessary performance gains. Near-term developments will likely focus on "Edge AI," where the same token-processing efficiency found in data centers is brought to billions of consumer devices, enabling truly private, local AI assistants.

Experts predict that by 2028, the industry will see the first commercial integration of quantum-classical hybrid systems, specifically for materials science and drug discovery. The challenge remains the massive capital expenditure required to stay at the cutting edge; with a single 2nm fab now costing upwards of $30 billion, the "barrier to entry" has never been higher. This will likely lead to further specialization, where a few mega-foundries provide the "compute utility" while a vast ecosystem of startups designs specialized "chiplets" for niche applications.

Conclusion: A New Era of Silicon Dominance

The semiconductor industry’s journey to a $1 trillion market is more than just a financial milestone; it is a testament to the fact that silicon has become the most important resource of the 21st century. The transition from a hardware-centric market to one driven by the "Token Economy" and application-level value marks the beginning of a new era in human productivity. The key takeaways are clear: the AI supercycle is real, the demand for compute is structural rather than cyclical, and the race for 2nm leadership will define the geopolitical balance of the next decade.

In the history of technology, this period will likely be remembered as the moment when "intelligence" became a scalable, manufactured commodity. For investors and industry watchers, the coming months will be critical as the first 2nm products hit the market and the "inference wave" begins to dominate data center revenue. The industry is no longer just building chips; it is building the brain of the future global economy.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.