India is rapidly accelerating its strategic push to establish a robust domestic semiconductor industry, a move poised to fundamentally reshape its economic landscape and solidify its position as a global technology powerhouse. Driven by a proactive government framework and an unprecedented surge in private investment, the nation is transitioning from a consumer of chips to a significant producer, aiming for technological self-reliance and substantial economic growth. This concerted effort marks a pivotal moment, signaling India's intent to become a critical node in the global semiconductor supply chain and a major hub for innovation and electronics manufacturing in the immediate future.

The immediate significance of this development is profound. India's semiconductor strategy has swiftly transitioned from policy blueprints to active implementation, with three Indian chip facilities anticipated to begin commercial production as early as 2026. This rapid shift to execution, validated by increasing private capital flow alongside government incentives, underscores the effectiveness of India's policy framework in creating a conducive environment for semiconductor manufacturing. It lays a stable foundation for sustained, long-term private sector involvement, addressing the nation's surging domestic demand for chips across critical sectors like mobile devices, IT, automotive, 5G infrastructure, and artificial intelligence, thereby reducing import dependency and fostering a vertically integrated ecosystem.

India's Chip Blueprint: From Policy to Production

India's strategic framework to cultivate its domestic semiconductor industry is meticulously designed and spearheaded by the India Semiconductor Mission (ISM), launched in December 2021 with a substantial financial commitment of approximately $10 billion (₹76,000 crore). Operating under the Ministry of Electronics and Information Technology (MeitY), the ISM acts as the nodal agency for investment screening and scheme implementation across the entire semiconductor value chain.

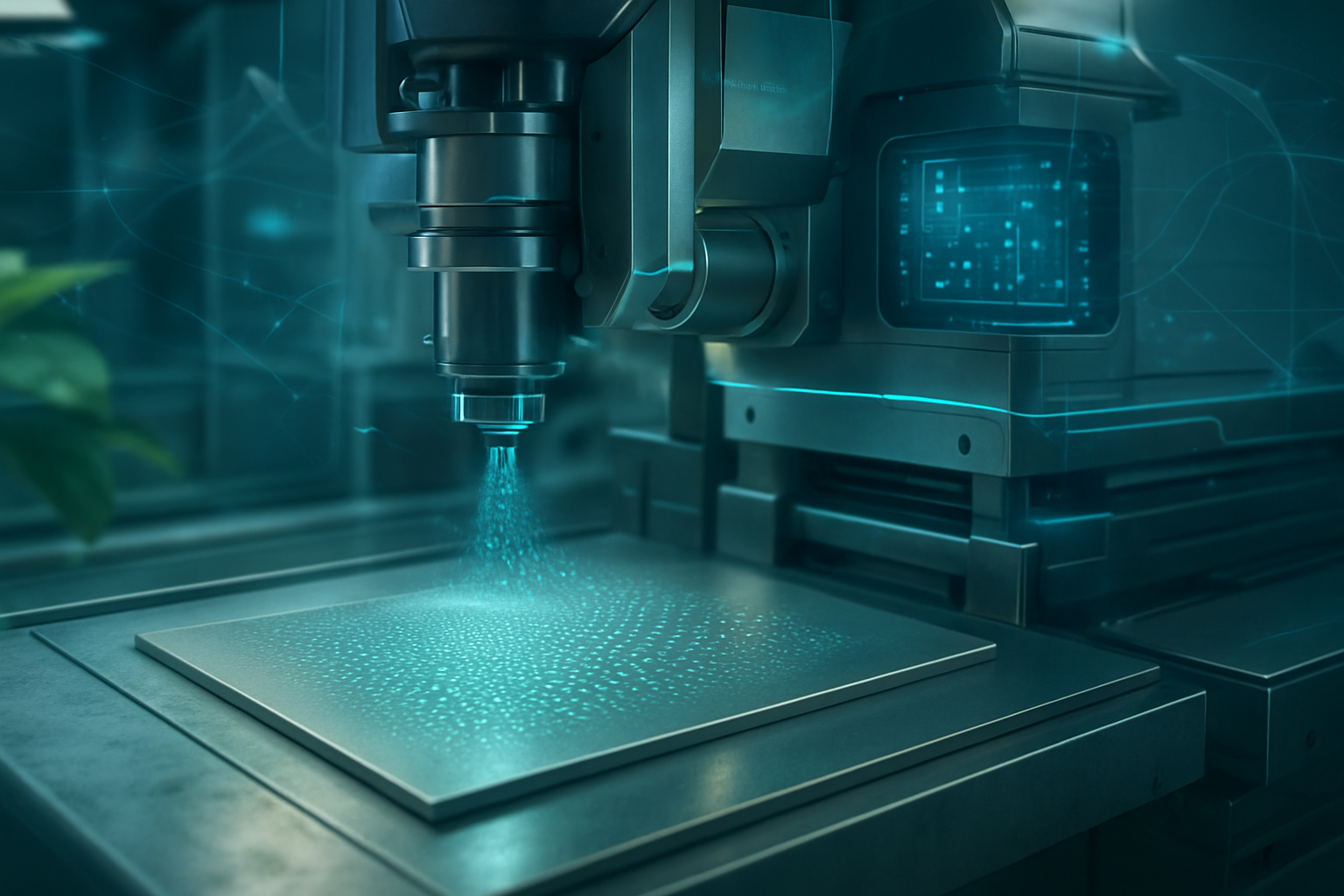

The core of this strategy involves comprehensive fiscal support, offering significant financial incentives, including up to 50% of the project cost for setting up semiconductor fabrication plants (fabs) and 50% of the capital expenditure for compound semiconductor fabs, silicon photonics, sensors, and Assembly, Testing, Marking, and Packaging (ATMP)/Outsourced Semiconductor Assembly and Test (OSAT) facilities. Notably, recent modifications ensure a 50% subsidy for all node sizes, reflecting a pragmatic approach to initially focus on trailing-edge nodes before progressing towards leading-edge technologies. This flexibility is a key differentiator from earlier, less successful attempts, which often aimed for leading-edge technology without sufficient foundational support.

Further bolstering this push is the Design Linked Incentive (DLI) Scheme, a vital component of the ISM aimed at fostering a full-stack chip design ecosystem. It provides financial support to semiconductor startups and Micro, Small, and Medium Enterprises (MSMEs) to recover design costs, scale commercialization, and develop intellectual property. As of July 2025, 23 chip design projects have been approved, and 72 companies have gained access to industry-grade Electronic Design Automation (EDA) tools, demonstrating tangible progress. This focus on design, where India already contributes 30% to global chip design, leverages an existing strength to accelerate its position in high-value segments. Initial reactions from the AI research community and industry experts have been largely positive, viewing India's holistic approach – encompassing design, fabrication, and packaging – as a more sustainable and robust strategy compared to fragmented efforts in the past. The commitment to indigenous innovation, exemplified by the expected unveiling of India's first indigenous semiconductor chip, Vikram-32, by late 2025, further reinforces confidence in the nation's long-term vision.

Corporate Catalysts: How Giants and Startups Are Shaping India's Chip Future

The burgeoning semiconductor landscape in India is attracting significant investment from both global tech giants and ambitious domestic players, poised to reshape competitive dynamics and create new market opportunities. This influx of capital and expertise signals a powerful endorsement of India's strategic vision and its potential to emerge as a formidable force in the global chip industry.

Among the most prominent beneficiaries and drivers of this development are companies like Micron Technology (NASDAQ: MU), which in June 2023, announced a substantial investment of approximately $2.71 billion (₹22,516 crore) to establish an advanced Assembly, Testing, Marking, and Packaging (ATMP) facility in Sanand, Gujarat. This facility, already under setup, represents a critical step in building out India's manufacturing capabilities. Similarly, the Tata Group, through Tata Electronics Private Limited, has committed a staggering $10 billion investment in a semiconductor fab, alongside Tata Semiconductor Assembly and Test (TSAT) setting up a $3.3 billion ATMP unit in Morigaon, Assam. These massive investments from established industrial conglomerates underscore the scale of ambition and the confidence in India's long-term semiconductor prospects.

The competitive implications for major AI labs and tech companies are significant. As India develops its indigenous manufacturing capabilities, it offers a diversified and potentially more resilient supply chain alternative to existing hubs. This could reduce reliance on single regions, a critical factor given recent geopolitical tensions and supply chain disruptions. Companies that partner with or establish operations in India stand to benefit from government incentives, a vast talent pool, and access to a rapidly growing domestic market. The focus on the entire value chain, from design to packaging, also creates opportunities for specialized equipment manufacturers like Applied Materials (NASDAQ: AMAT), which is investing $400 million in an engineering center, and Lam Research (NASDAQ: LRCX), pledging $25 million for a semiconductor training lab. This comprehensive approach ensures that the ecosystem is supported by critical infrastructure and talent development.

Furthermore, the Design Linked Incentive (DLI) scheme is fostering a vibrant startup ecosystem. Indian semiconductor startups have already garnered $43.9 million in private investment, with companies like Netrasemi, Mindgrove Technologies (developing India's first commercial-grade high-performance microcontroller SoC), and Fermionic Design innovating in areas such as AI, IoT, and satellite communication chips. This surge in homegrown innovation not only creates new market entrants but also positions India as a hub for cutting-edge IP development, potentially disrupting existing product lines and services that rely solely on imported chip designs. The strategic advantages gained by these early movers, both large corporations and nimble startups, will be crucial in shaping their market positioning in the evolving global technology landscape.

India's Chip Ambition: Reshaping the Global Tech Tapestry

India's aggressive push into the semiconductor industry is more than just an economic initiative; it's a strategic move that significantly alters the broader AI landscape and global technology trends. By aiming for self-reliance in chip manufacturing, India is addressing a critical vulnerability exposed by recent global supply chain disruptions and geopolitical shifts, positioning itself as a vital alternative in a concentrated market.

This fits into the broader AI landscape by securing the foundational hardware necessary for advanced AI development and deployment. AI models and applications are inherently compute-intensive, requiring a constant supply of high-performance chips. By building domestic fabrication capabilities, India ensures a stable and secure supply for its rapidly expanding AI sector, from data centers to edge devices. The indigenous development of chips, such as the upcoming Vikram-32, will not only cater to domestic demand but also foster innovation tailored to India's unique market needs and technological aspirations, including applications in smart cities, healthcare, and defense. This move also contributes to the global trend of decentralizing semiconductor manufacturing, moving away from a few dominant regions to a more distributed and resilient model.

The impacts are multi-faceted. Economically, India's semiconductor market, valued at approximately $38 billion in 2023, is projected to surge to $100-110 billion by 2030, demonstrating a compound annual growth rate (CAGR) of 13.8%. This growth is expected to generate 1 million jobs by 2026, boosting employment and skill development across various technical domains. Geopolitically, India's emergence as a reliable alternative in the global semiconductor supply chain enhances its strategic importance and contributes to global stability by diversifying critical technology sources. However, potential concerns include the immense capital expenditure required, the complexity of establishing a mature ecosystem, and the challenge of attracting and retaining highly specialized talent. Comparisons to previous AI milestones and breakthroughs highlight that while AI software advancements often grab headlines, the underlying hardware infrastructure, like semiconductors, is equally critical. India's strategy acknowledges this foundational truth, ensuring that its AI ambitions are supported by robust, domestically controlled hardware.

The Road Ahead: India's Semiconductor Horizon

The future trajectory of India's semiconductor industry is marked by ambitious targets and significant expected developments, poised to further solidify its standing on the global stage. Near-term, the focus remains on operationalizing the approved projects and bringing the first set of facilities into commercial production. The anticipated commencement of production from three Indian chip facilities as early as 2026 will be a critical milestone, demonstrating tangible progress from policy to product.

In the long term, experts predict that India will continue its strategic progression from trailing-edge to more advanced node technologies, driven by sustained private investment and continuous government support. The goal, as articulated by Union Minister Ashwini Vaishnaw, is for India to achieve semiconductor manufacturing capabilities on par with leading global chipmaking nations like the US and China by 2031-2032. This will involve not just manufacturing but also significant advancements in research and development, fostering indigenous intellectual property, and expanding the design ecosystem. Potential applications and use cases on the horizon are vast, ranging from powering India's burgeoning AI and IoT sectors, enabling advanced 5G and future 6G communication infrastructure, to enhancing automotive electronics and defense technologies. The development of specialized chips for AI accelerators and edge computing will be particularly crucial as AI integration deepens across industries.

However, several challenges need to be addressed. Securing access to advanced technology licenses, establishing a robust supply chain for critical raw materials and equipment, and continuously upskilling a vast workforce to meet the highly specialized demands of semiconductor manufacturing are paramount. Furthermore, maintaining a competitive incentive structure and ensuring policy stability will be crucial to attract and retain global players. Experts predict that while the initial phase will focus on establishing foundational capabilities, subsequent phases will see India making significant inroads into more complex fabrication processes and specialized chip designs, driven by a growing pool of engineering talent and increasing global collaborations. The continuous evolution of the Design Linked Incentive (DLI) scheme and the active participation of state governments will be key enablers for this growth.

India's Chip Renaissance: A New Era for Global Tech

India's strategic pivot to cultivate a robust domestic semiconductor industry represents a monumental shift with far-reaching implications for the global technology landscape. The key takeaways underscore a nation that has moved beyond aspirations to concrete execution, evidenced by substantial government backing through the India Semiconductor Mission and an unprecedented surge in private investment from both international giants and homegrown conglomerates. This combined force is rapidly laying the groundwork for a comprehensive semiconductor ecosystem, spanning design, fabrication, and packaging.

The significance of this development in AI history cannot be overstated. As AI continues its exponential growth, the demand for sophisticated, high-performance chips will only intensify. By building its own chip manufacturing capabilities, India is not merely diversifying its economy; it is securing the foundational hardware necessary to power its AI ambitions and contribute to the global AI revolution. This self-reliance ensures resilience against future supply chain shocks and positions India as a strategic partner in the development of cutting-edge AI technologies. The long-term impact will see India emerge not just as a consumer, but as a critical producer and innovator in the global semiconductor and AI arenas, fostering indigenous IP and creating a vast pool of highly skilled talent.

In the coming weeks and months, the world will be watching for several key indicators: the progress of the Micron and Tata facilities towards commercial production, further announcements of private investments, and the unveiling of indigenous chip designs. The success of the DLI scheme in nurturing startups and the continued evolution of state-level policies will also be crucial barometers of India's sustained momentum. India's chip renaissance is not just an economic story; it's a testament to national ambition, technological foresight, and a determined push to redefine its role in shaping the future of global technology.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.