As we close out 2025, the narrative of the artificial intelligence industry has undergone a radical transformation. For years, the "bigger is better" philosophy dominated, with tech giants racing to build trillion-parameter models that required the power of small cities to operate. However, the defining trend of 2025 has been the "Inference Inflection Point"—the moment when Small Language Models (SLMs) like Microsoft's Phi-4 and Google's Gemma 3 proved that high-performance intelligence no longer requires a massive data center. This shift toward "Edge AI" has brought sophisticated reasoning, native multimodality, and near-instantaneous response times directly to the devices in our pockets and on our desks.

The immediate significance of this development cannot be overstated. By moving the "brain" of the AI from the cloud to the local hardware, the industry has effectively solved the three biggest hurdles to mass AI adoption: cost, latency, and privacy. In late 2025, the release of the "AI PC" and "AI Phone" as market standards has turned artificial intelligence into a utility as ubiquitous and invisible as electricity. No longer a novelty accessed through a chat window, AI is now an integrated layer of the operating system, capable of seeing, hearing, and acting on a user's behalf without ever sending a single byte of sensitive data to an external server.

The Technical Triumph of the Small

The technical leap from the experimental SLMs of 2024 to the production-grade models of late 2025 is staggering. Microsoft (NASDAQ: MSFT) recently expanded its Phi-4 family, headlined by a 14.7-billion parameter base model and a highly optimized 3.8B "mini" variant. Despite its diminutive size, the Phi-4-mini boasts a 128K context window and utilizes Test-Time Compute (TTC) algorithms to achieve reasoning parity with the legendary GPT-4 on logic and coding benchmarks. This efficiency is driven by "educational-grade" synthetic data training, where the model learns from high-quality, curated logic chains rather than the unfiltered noise of the open internet.

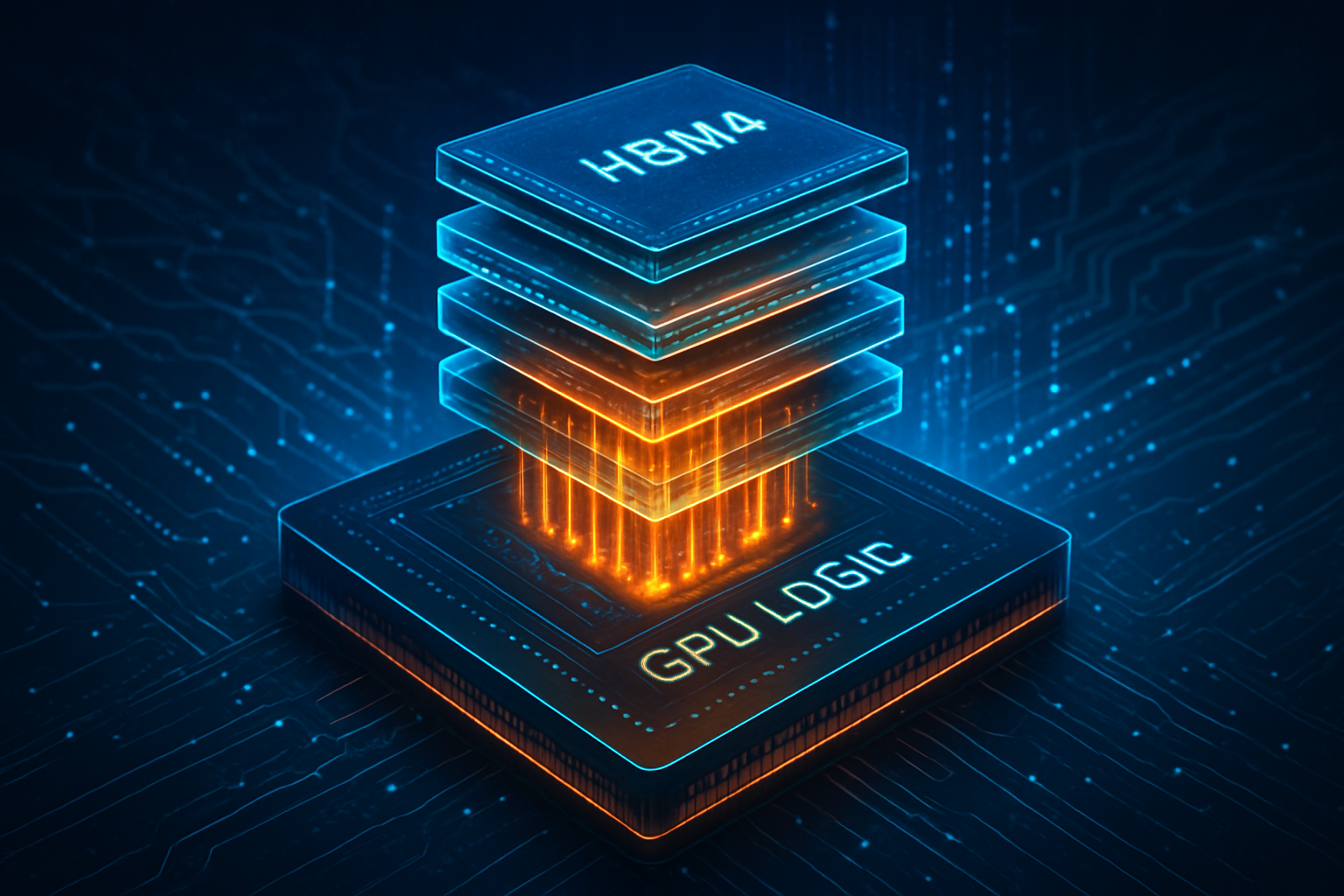

Simultaneously, Google (NASDAQ: GOOGL) has released Gemma 3, a natively multimodal family of models. Unlike previous iterations that required separate encoders for images and text, Gemma 3 processes visual and linguistic data in a single, unified stream. The 4B parameter version, designed specifically for the Android 16 kernel, uses a technique called Per-Layer Embedding (PLE). This allows the model to stream its weights from high-speed storage (UFS 4.0) rather than occupying a device's entire RAM, enabling mid-range smartphones to perform real-time visual translation and document synthesis locally.

This technical evolution differs from previous approaches by prioritizing "inference efficiency" over "training scale." In 2023 and 2024, small models were often viewed as "toys" or specialized tools for narrow tasks. In late 2025, however, the integration of 80 TOPS (Trillions of Operations Per Second) NPUs in consumer hardware has changed the math. Initial reactions from the research community have been overwhelmingly positive, with experts noting that the "reasoning density"—the amount of intelligence per parameter—has increased by nearly 5x in just eighteen months.

A New Hardware Super-Cycle and the Death of the API

The business implications of the SLM revolution have sent shockwaves through Silicon Valley. The shift from cloud-based AI to edge-based AI has ignited a massive hardware refresh cycle, benefiting silicon pioneers like Qualcomm (NASDAQ: QCOM) and Intel (NASDAQ: INTC). Qualcomm’s Snapdragon X2 Elite has become the gold standard for the "AI PC," providing the local horsepower necessary to run 15B parameter models at 40 tokens per second. This has allowed Qualcomm to aggressively challenge the traditional dominance of x86 architecture in the laptop market, as battery life and NPU performance become the primary metrics for consumers.

For the "Magnificent Seven," the strategy has shifted from selling tokens to selling ecosystems. Apple (NASDAQ: AAPL) has capitalized on this by marketing its "Apple Intelligence" as a privacy-exclusive feature, driving record iPhone 17 Pro sales. Meanwhile, Microsoft and Google are moving away from "per-query" API billing for routine tasks. Instead, they are bundling SLMs into their operating systems to create "Agentic OS" environments. This has put immense pressure on traditional AI API providers; when a local, free model can handle 80% of an enterprise's summarization and coding needs, the market for expensive cloud-based inference begins to shrink to only the most complex "frontier" tasks.

This disruption extends deep into the SaaS sector. Companies like Salesforce (NYSE: CRM) are now deploying self-hosted SLMs for their clients, allowing for a 20x reduction in operational costs compared to cloud-based LLMs. The competitive advantage has shifted to those who can provide "Sovereign AI"—intelligence that stays within the corporate firewall. As a result, the "AI-as-a-Service" model is being rapidly replaced by "Hardware-Integrated Intelligence," where the value is found in the seamless orchestration of local and cloud resources.

Privacy, Power, and the Greening of AI

The wider significance of the SLM rise is most visible in the realms of privacy and environmental sustainability. For the first time since the dawn of the internet, users can enjoy personalized, high-level digital assistance without the "privacy tax" of data harvesting. In highly regulated sectors like healthcare and finance, the ability to run models like Phi-4 or Gemma 3 locally has enabled a wave of innovation that was previously blocked by compliance concerns. "Private AI" is no longer a luxury for the tech-savvy; it is the default state for the modern enterprise.

From an environmental perspective, the shift to the edge is a necessity. The energy demands of hyperscale data centers were reaching a breaking point in early 2025. Local inference on NPUs is roughly 10,000 times more energy-efficient than cloud inference when factoring in the massive cooling and transmission costs of data centers. By moving routine tasks—like email drafting, photo editing, and schedule management—to local hardware, the tech industry has found a path toward AI scaling that doesn't involve the catastrophic depletion of local water and power grids.

However, this transition is not without its concerns. The rise of SLMs has intensified the "Data Wall" problem. As these models are increasingly trained on synthetic data generated by other AIs, researchers warn of "Model Collapse," where the AI begins to lose the nuances of human creativity and enters a feedback loop of mediocrity. Furthermore, the "Digital Divide" is taking a new form: the gap is no longer just about who has internet access, but who has the "local compute" to run the world's most advanced intelligence locally.

The Horizon: Agentic Wearables and Federated Learning

Looking toward 2026 and 2027, the next frontier for SLMs is "On-Device Personalization." Through techniques like Federated Learning and Low-Rank Adaptation (LoRA), your devices will soon begin to learn from you in real-time. Instead of a generic model, your phone will host a "Personalized Adapter" that understands your specific jargon, your family's schedule, and your professional preferences, all without ever uploading that personal data to the cloud. This "reflexive AI" will be able to update its behavior in milliseconds based on the user's immediate physical context.

We are also seeing the convergence of SLMs with wearable technology. The upcoming generation of AR glasses from Meta (NASDAQ: META) and smart hearables are being designed around "Ambient SLMs." These models will act as a constant, low-power layer of intelligence, providing real-time HUD overlays or isolating a single voice in a noisy room. Experts predict that by 2027, the concept of "prompting" an AI will feel archaic; instead, SLMs will function as "proactive agents," anticipating needs and executing multi-step workflows across different apps autonomously.

The New Era of Ubiquitous Intelligence

The rise of Small Language Models marks the end of the "Cloud-Only" era of artificial intelligence. In 2025, we have seen the democratization of high-performance AI, moving it from the hands of a few tech giants with massive server farms into the pockets of billions of users. The success of models like Phi-4 and Gemma 3 has proven that intelligence is not a function of size alone, but of efficiency, data quality, and hardware integration.

As we look forward, the significance of this development in AI history will likely be compared to the transition from mainframes to personal computers. We have moved from "Centralized Intelligence" to "Distributed Wisdom." In the coming months, watch for the arrival of "Hybrid AI" systems that seamlessly hand off tasks between local NPUs and cloud-based "frontier" models, creating a spectrum of intelligence that is always available, entirely private, and remarkably sustainable. The titan has indeed been shrunk, and in doing so, it has finally become useful for everyone.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.