The landscape of semiconductor engineering has undergone a tectonic shift as Synopsys Inc. (NASDAQ: SNPS) officially completed its $35 billion acquisition of Ansys Inc., marking the largest merger in the history of electronic design automation (EDA). Finalized following a grueling 18-month regulatory review that spanned three continents, the deal represents a definitive pivot from traditional chip-centric design to a holistic "Silicon-to-Systems" philosophy. By uniting the world’s leading chip design software with the gold standard in physics-based simulation, the combined entity aims to solve the physics-defying challenges of the AI era, where heat, stress, and electromagnetic interference are now as critical to success as logic gates.

The immediate significance of this merger lies in its timing. As of early 2026, the industry is racing toward the "Angstrom Era," with 2nm and 1.8A nodes entering mass production at foundries like Taiwan Semiconductor Manufacturing Company (NYSE: TSM) and Intel (NASDAQ: INTC). At these scales, the physical environment surrounding a chip is no longer a peripheral concern but a primary failure mode. The Synopsys-Ansys integration provides the first unified platform capable of simulating how a billion-transistor processor interacts with its package, its cooling system, and the electromagnetic noise of a modern AI data center—all before a single physical prototype is ever manufactured.

A Unified Architecture for the Angstrom Era

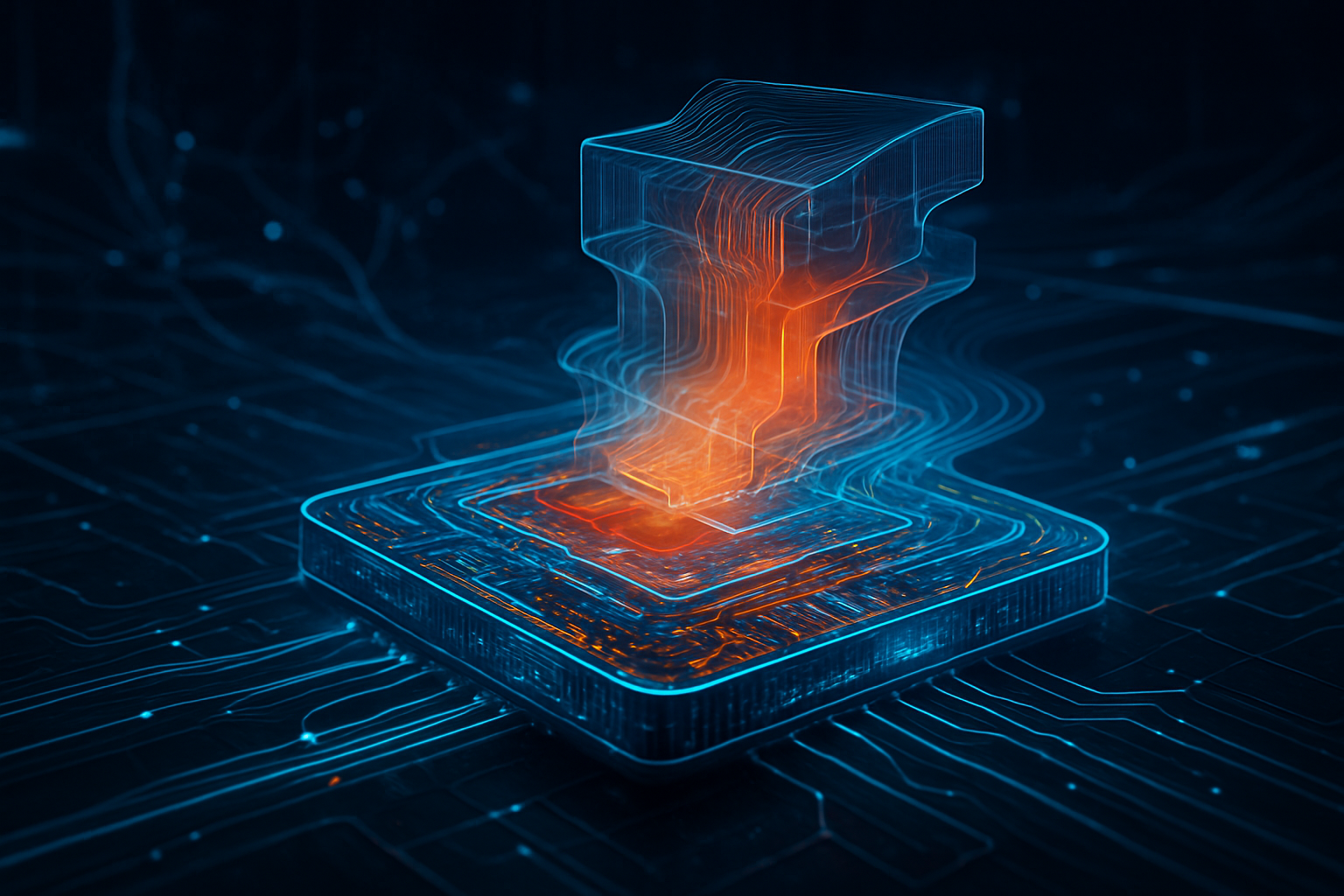

The technical backbone of the merger is the deep integration of Ansys’s multiphysics solvers directly into the Synopsys design stack. Historically, chip design and physics simulation were siloed workflows; a designer would layout a chip in Synopsys tools and then "hand off" the design to a simulation team using Ansys to check for thermal or structural issues. This sequential process often led to "late-stage surprises" where heat hotspots or mechanical warpage forced engineers back to the drawing board, costing millions in lost time. The new "Shift-Left" workflow eliminates this friction by embedding tools like Ansys RedHawk-SC and HFSS directly into the Synopsys 3DIC Compiler, allowing for real-time, physics-aware design.

This convergence is particularly vital for the rise of multi-die systems and 3D-ICs. As the industry moves away from monolithic chips toward heterogeneous "chiplets" stacked vertically, the complexity of power delivery and heat dissipation has grown exponentially. The combined company's new "3Dblox" standard allows designers to create a unified data model that accounts for thermal-aware placement—where AI-driven algorithms automatically reposition components to prevent heat build-up—and electromagnetic sign-off for high-speed die-to-die connectivity like UCIe. Initial benchmarks from early adopters suggest that this integrated approach can reduce design cycle times by as much as 40% for advanced 3D-stacked AI accelerators.

Furthermore, the role of artificial intelligence has been elevated through the Synopsys.ai suite, which now leverages Ansys solvers as "fast native engines." These AI-driven "Design Space Optimization" (DSO) tools can evaluate thousands of potential layouts in minutes, using Ansys’s 50 years of physics data to predict structural reliability and power integrity. Industry experts, including researchers from the IEEE, have hailed this as the birth of "Physics-AI," where generative models are no longer just predicting code or text, but are actively synthesizing the physical architecture of the next generation of intelligent machines.

Competitive Moats and the Industry Response

The completion of the merger has sent shockwaves through the competitive landscape, effectively creating a "one-stop-shop" that rivals struggle to match. By owning the dominant tools for both the logical and physical domains, Synopsys has built a formidable strategic moat. Major tech giants like Nvidia (NASDAQ: NVDA) and AMD (NASDAQ: AMD), along with hyperscalers such as Amazon (NASDAQ: AMZN) and Microsoft (NASDAQ: MSFT), stand to benefit most from this consolidation. These companies, which are increasingly designing their own custom silicon, can now leverage a singular, vertically integrated toolchain to accelerate their time-to-market for specialized AI hardware.

Competitors have been forced to respond with aggressive defensive maneuvers. Cadence Design Systems (NASDAQ: CDNS) recently bolstered its own multiphysics portfolio through the multi-billion dollar acquisition of Hexagon’s MSC Software, while Siemens (OTC: SIEGY) integrated Altair Engineering into its portfolio to connect chip design with broader industrial manufacturing. However, Synopsys’s head start in AI-native integration gives it a distinct advantage. Meanwhile, Keysight Technologies (NYSE: KEYS) has emerged as an unexpected winner; to appease regulators, Synopsys was required to divest several high-profile assets to Keysight, including its Optical Solutions Group, effectively turning Keysight into a more capable fourth player in the high-end simulation market.

Market analysts suggest that this merger may signal the end of the "best-of-breed" era in EDA, where companies would mix and match tools from different vendors. The sheer efficiency of the Synopsys-Ansys integrated stack makes "mixed-vendor" flows significantly more expensive and error-prone. This has led to concerns among smaller fabless startups about potential "vendor lock-in," as the cost of switching away from the dominant Synopsys ecosystem becomes prohibitive. Nevertheless, for the "Titans" of the industry, the merger offers a clear path to managing the systemic complexity that has become the hallmark of the post-Moore’s Law world.

The Dawn of "SysMoore" and the AI Virtuous Cycle

Beyond the immediate business implications, the merger represents a milestone in the "SysMoore" era—a term coined to describe the transition from transistor scaling to system-level scaling. As the physical limits of silicon are reached, performance gains must come from how chips are packaged and integrated into larger systems. This merger is the first software-level acknowledgment that the system is the new "chip." It fits into a broader trend where AI is creating a virtuous cycle: AI-designed chips are being used to power more advanced AI models, which in turn are used to design even more efficient chips.

The environmental significance of this development is also profound. AI-designed chips are notoriously power-hungry, but the "Shift-Left" approach allows engineers to find hidden energy efficiencies that human designers would likely miss. By using "Digital Twins"—virtual replicas of entire data centers powered by Ansys simulation—companies can optimize cooling and airflow at the system level, potentially reducing the massive carbon footprint of generative AI training. However, some critics remain concerned that the consolidation of such powerful design tools into a single entity could stifle the very innovation needed to solve these global energy challenges.

This milestone is often compared to the failed Nvidia-ARM merger of 2022. Unlike that deal, which was blocked due to concerns about Nvidia controlling a neutral industry standard, the Synopsys-Ansys merger is viewed as "complementary" rather than "horizontal." It doesn't consolidate competitors; it integrates neighbors in the supply chain. This regulatory approval signals a shift in how governments view tech consolidation in the age of strategic AI competition, prioritizing the creation of robust national champions capable of leading the global hardware race.

The Road Ahead: 1.8A and Beyond

Looking toward the future, the new Synopsys-Ansys entity faces a roadmap defined by both immense technical opportunity and significant geopolitical risk. In the near term, the integration will focus on supporting the 1.8A (18 Angstrom) node. These chips will utilize "Backside Power Delivery" and GAAFET transistors, technologies that are incredibly sensitive to thermal and electromagnetic fluctuations. The combined company’s success will largely be measured by how effectively it helps foundries like TSMC and Intel bring these nodes to high-yield mass production.

On the horizon, we can expect the launch of "Synopsys Multiphysics AI," a platform that could potentially automate the entire physical verification process. Experts predict that by 2027, "Agentic AI" will be able to take a high-level architectural description and autonomously generate a fully simulated, physics-verified chip layout with minimal human intervention. This would democratize high-end chip design, allowing smaller startups to compete with the likes of Apple (NASDAQ: AAPL) by providing them with the "virtual engineering teams" previously only available to the world’s wealthiest corporations.

However, challenges remain. The company must navigate the increasingly complex US-China trade landscape. In late 2025, Synopsys faced pressure to limit certain software exports to China, a move that could impact a significant portion of its revenue. Furthermore, the internal task of unifying two massive, decades-old software codebases is a Herculean engineering feat. If the integration of the databases is not handled seamlessly, the promised "single source of truth" for designers could become a source of technical debt and software bugs.

A New Chapter in Computing History

The finalization of the Synopsys-Ansys merger is more than just a corporate transaction; it is the starting gun for the next decade of computing. By bridging the gap between the digital logic of EDA and the physical reality of multiphysics, the industry has finally equipped itself with the tools necessary to build the "intelligent systems" of the future. The key takeaways for the industry are clear: system-level integration is the new frontier, AI is the primary design architect, and physics is no longer a constraint to be checked, but a variable to be optimized.

As we move into 2026, the significance of this development in AI history cannot be overstated. We have moved from a world where AI was merely a workload to a world where AI is the master craftsman of its own hardware. In the coming months, the industry will watch closely for the first "Tape-Outs" of 2nm AI chips designed entirely within the integrated Synopsys-Ansys environment. Their performance and thermal efficiency will be the ultimate testament to whether this $35 billion gamble has truly changed the world.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.