The United States is witnessing a monumental resurgence in semiconductor manufacturing, a strategic pivot driven by national security imperatives, economic resilience, and a renewed commitment to technological leadership. At the heart of this transformative movement lies Arizona, rapidly emerging as the blueprint for a new era of domestic chip production. Decades of offshoring had left the nation vulnerable to supply chain disruptions and geopolitical risks, but a concerted effort, spearheaded by landmark legislation and massive private investments, is now bringing advanced chip fabrication back to American soil.

This ambitious re-shoring initiative is not merely about manufacturing; it's about reclaiming a vital industry that underpins virtually every aspect of modern life, from defense systems and artificial intelligence to consumer electronics and critical infrastructure. The concentrated investment and development in Arizona signal a profound shift, promising to reshape the global technology landscape and solidify America's position at the forefront of innovation.

Forging a New Era: The Technical and Strategic Underpinnings

The strategic imperative to re-shore semiconductor manufacturing stems from critical vulnerabilities exposed by decades of offshoring. The COVID-19 pandemic starkly illustrated the fragility of global supply chains, as chip shortages crippled industries worldwide. Beyond economic disruption, the reliance on foreign-sourced semiconductors poses significant national security risks, given their foundational role in military technology, secure communications, and cybersecurity. Regaining a substantial share of global semiconductor manufacturing, which had dwindled from nearly 40% in 1990 to a mere 12% in 2022, is therefore a multifaceted endeavor aimed at bolstering both economic prosperity and national defense.

A cornerstone of this resurgence is the CHIPS and Science Act, passed in August 2022. This landmark legislation allocates approximately $52 billion in grants and incentives, coupled with a 25% advanced manufacturing investment tax credit, specifically designed to catalyze domestic semiconductor production and R&D. The Act also earmarks substantial funding for research and development and workforce training initiatives, crucial for bridging the anticipated talent gap. Since its enactment, the CHIPS Act has spurred over $600 billion in announced private sector investments across 130 projects in 28 states, with projections indicating a tripling of U.S. semiconductor manufacturing capacity between 2022 and 2032 – the highest growth rate globally.

Arizona, often dubbed the "Silicon Desert," has become a critical hub and a national blueprint for this revitalized industry. Its appeal is rooted in a robust, pre-existing semiconductor ecosystem, dating back to Motorola's (NYSE: MSI) research lab in Phoenix in 1949 and Intel's (NASDAQ: INTC) arrival in 1980. This history has cultivated a network of suppliers, research institutions, and a skilled workforce. The state also offers a favorable business environment, including a competitive corporate tax structure, tax credits, a minimalist regulatory approach, and competitive costs for labor, land, and operations. Furthermore, the demanding requirements of semiconductor fabrication plants (fabs) for reliable infrastructure are met by Arizona's energy stability and abundant land with high seismic stability, essential for sensitive manufacturing processes. Proactive partnerships with educational institutions like Arizona State University are also diligently building a strong talent pipeline to meet the industry's burgeoning demand for engineers and skilled technicians.

Competitive Shifts: How Arizona's Rise Impacts the Tech Landscape

The influx of semiconductor manufacturing into Arizona is poised to significantly reshape the competitive landscape for AI companies, tech giants, and startups alike. Companies that stand to benefit most are those deeply reliant on a stable, secure, and geographically diverse supply of advanced chips, including major cloud providers, automotive manufacturers, and defense contractors. The reduced lead times and enhanced supply chain resilience offered by domestic production will mitigate risks and potentially accelerate innovation cycles.

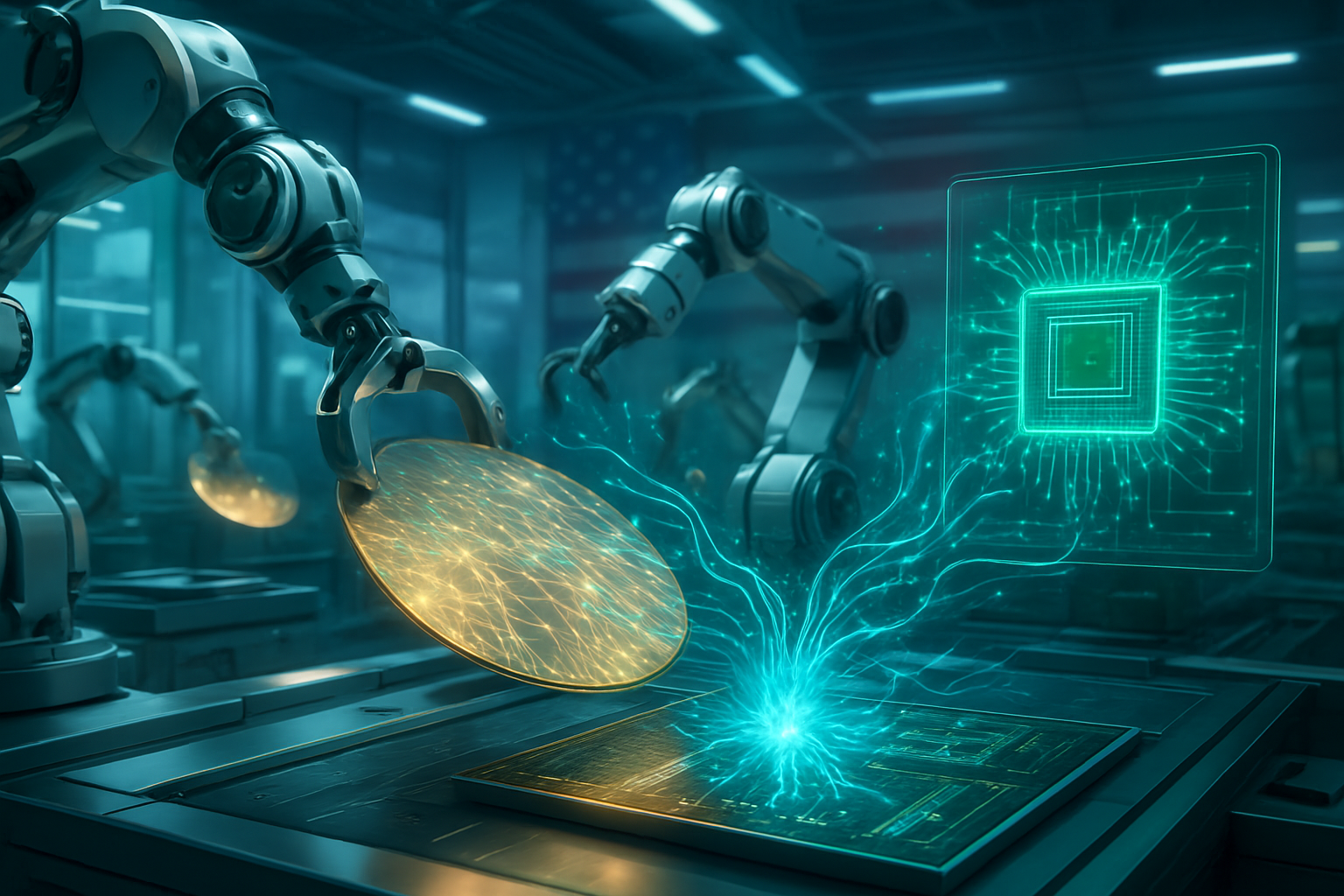

Major players like Intel (NASDAQ: INTC) and TSMC (Taiwan Semiconductor Manufacturing Company) are at the forefront of this transformation. Intel has committed significant investments, including $20 billion in Arizona for two new chip-making facilities in Chandler, expanding its Ocotillo campus to a total of six factories. The company also received $8.5 billion in CHIPS Act funding to support four fabs across Arizona, New Mexico, Ohio, and Oregon, with an ambitious goal to become the world's second-largest foundry by 2030. TSMC, the world's largest contract chipmaker, initially announced a $12 billion investment in Arizona in 2020, which has dramatically expanded to a total commitment of $65 billion for three state-of-the-art manufacturing facilities in Phoenix. TSMC further plans to invest $100 billion for five new fabrication facilities in Arizona, bringing its total U.S. investment to $165 billion, supported by $6.6 billion in CHIPS Act funding. Other significant recipients of CHIPS Act funding and investors in U.S. production include Samsung Electronics (KRX: 005930), Micron Technology (NASDAQ: MU), and GlobalFoundries (NASDAQ: GFS).

This concentration of advanced manufacturing capabilities in Arizona will likely create a vibrant ecosystem, attracting ancillary industries, research institutions, and a new wave of startups focused on chip design, packaging, and related technologies. For tech giants, domestic production offers not only supply chain security but also closer collaboration opportunities with manufacturers, potentially leading to custom chip designs optimized for their specific AI workloads and data center needs. The competitive implications are clear: companies with access to these cutting-edge domestic fabs will gain a strategic advantage in terms of innovation speed, intellectual property protection, and market responsiveness, potentially disrupting existing product lines that rely heavily on overseas production.

Broader Significance: Reclaiming Technological Sovereignty

The resurgence of American semiconductor manufacturing, with Arizona as a pivotal hub, represents more than just an economic revival; it signifies a critical step towards reclaiming technological sovereignty. This initiative fits squarely into broader global trends of de-globalization and strategic decoupling, as nations increasingly prioritize self-sufficiency in critical technologies. The impacts are far-reaching, extending beyond the tech industry to influence geopolitical stability, national defense capabilities, and long-term economic resilience.

One of the most significant impacts is the enhanced security of the technology supply chain. By reducing reliance on a single geographic region, particularly Taiwan, which produces the vast majority of advanced logic chips, the U.S. mitigates risks associated with natural disasters, pandemics, and geopolitical tensions. This diversification is crucial for national security, ensuring uninterrupted access to the high-performance chips essential for defense systems, AI development, and critical infrastructure. The initiative also aims to re-establish American leadership in advanced manufacturing, fostering innovation and creating high-paying jobs across the country.

Potential concerns, however, include the substantial upfront costs and the challenge of competing with established foreign manufacturing ecosystems that benefit from lower labor costs and extensive government subsidies. Workforce development remains a critical hurdle, requiring sustained investment in STEM education and vocational training to meet the demand for highly skilled engineers and technicians. Despite these challenges, the current push represents a profound departure from previous industrial policies, comparable in ambition to historical milestones like the space race or the development of the internet. It signals a national commitment to securing the foundational technology of the 21st century.

The Road Ahead: Future Developments and Challenges

The coming years are expected to witness a rapid acceleration in the development and operationalization of these new semiconductor fabs in Arizona and across the U.S. Near-term developments will focus on bringing the initial phases of these multi-billion-dollar facilities online, ramping up production, and attracting a robust ecosystem of suppliers and ancillary services. Long-term, experts predict a significant increase in the domestic production of cutting-edge chips, including those critical for advanced AI, high-performance computing, and next-generation communication technologies.

Potential applications and use cases on the horizon are vast. A secure domestic supply of advanced chips will enable faster innovation in AI hardware, leading to more powerful and efficient AI models. It will also bolster the development of quantum computing, advanced robotics, and autonomous systems. Furthermore, the proximity of design and manufacturing will foster tighter collaboration, potentially accelerating the "chiplet" architecture trend, where specialized chip components are integrated to create highly customized and efficient processors.

However, significant challenges remain. Beyond the initial capital investment, sustained government support will be crucial to offset the higher operating costs in the U.S. compared to Asia. The ongoing global competition for talent, particularly in highly specialized fields like semiconductor engineering, will require continuous investment in education and immigration policies. Experts predict that while the U.S. will not fully decouple from global supply chains, it will achieve a much higher degree of strategic independence in critical semiconductor categories. The success of the "Arizona blueprint" will serve as a critical test case, influencing future investments and policy decisions in other high-tech sectors.

A New Dawn for American Manufacturing

The resurgence of American semiconductor manufacturing, with Arizona leading the charge, marks a pivotal moment in the nation's industrial history. The confluence of strategic necessity, robust government incentives through the CHIPS Act, and unprecedented private sector investment has ignited a powerful movement to re-shore a critical industry. This initiative is not merely about economic growth or job creation; it's about securing national interests, fostering technological leadership, and building resilience against future global disruptions.

The key takeaways are clear: the U.S. is committed to reclaiming its prominence in advanced manufacturing, with Arizona serving as a prime example of how a collaborative ecosystem of government, industry, and academia can drive transformative change. The significance of this development in AI history cannot be overstated, as a secure and innovative domestic chip supply will be foundational for the next generation of artificial intelligence advancements.

In the coming weeks and months, all eyes will be on the progress of these mega-fabs in Arizona. Watch for further announcements regarding production timelines, workforce development initiatives, and the continued expansion of the supply chain ecosystem. The success of this ambitious endeavor will not only redefine the future of American manufacturing but also profoundly shape the global technological and geopolitical landscape for decades to come.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.