The long-prophesied "post-silicon era" has officially arrived, signaling a paradigm shift in how the world builds and scales artificial intelligence. Researchers at the Georgia Institute of Technology, led by Professor Walter de Heer, have successfully created the world’s first functional semiconductor made from graphene—a single layer of carbon atoms known for its extraordinary strength and conductivity. By solving a two-decade-old physics puzzle known as the "bandgap problem," the team has paved the way for a new generation of electronics that could theoretically operate at speeds ten times faster than current silicon-based processors while consuming a fraction of the power.

As of early 2026, this breakthrough is no longer a mere laboratory curiosity; it has become the foundation for a multi-billion dollar pivot in the semiconductor industry. With silicon reaching its physical limits—hampering the growth of massive AI models and data centers—the introduction of a graphene-based semiconductor provides the necessary "escape velocity" for the next decade of AI innovation. This development is being hailed as the most significant milestone in material science since the invention of the transistor in 1947, promising to revitalize Moore’s Law and solve the escalating thermal and energy crises facing the global AI infrastructure.

Overcoming the "Off-Switch" Obstacle: The Science of Epitaxial Graphene

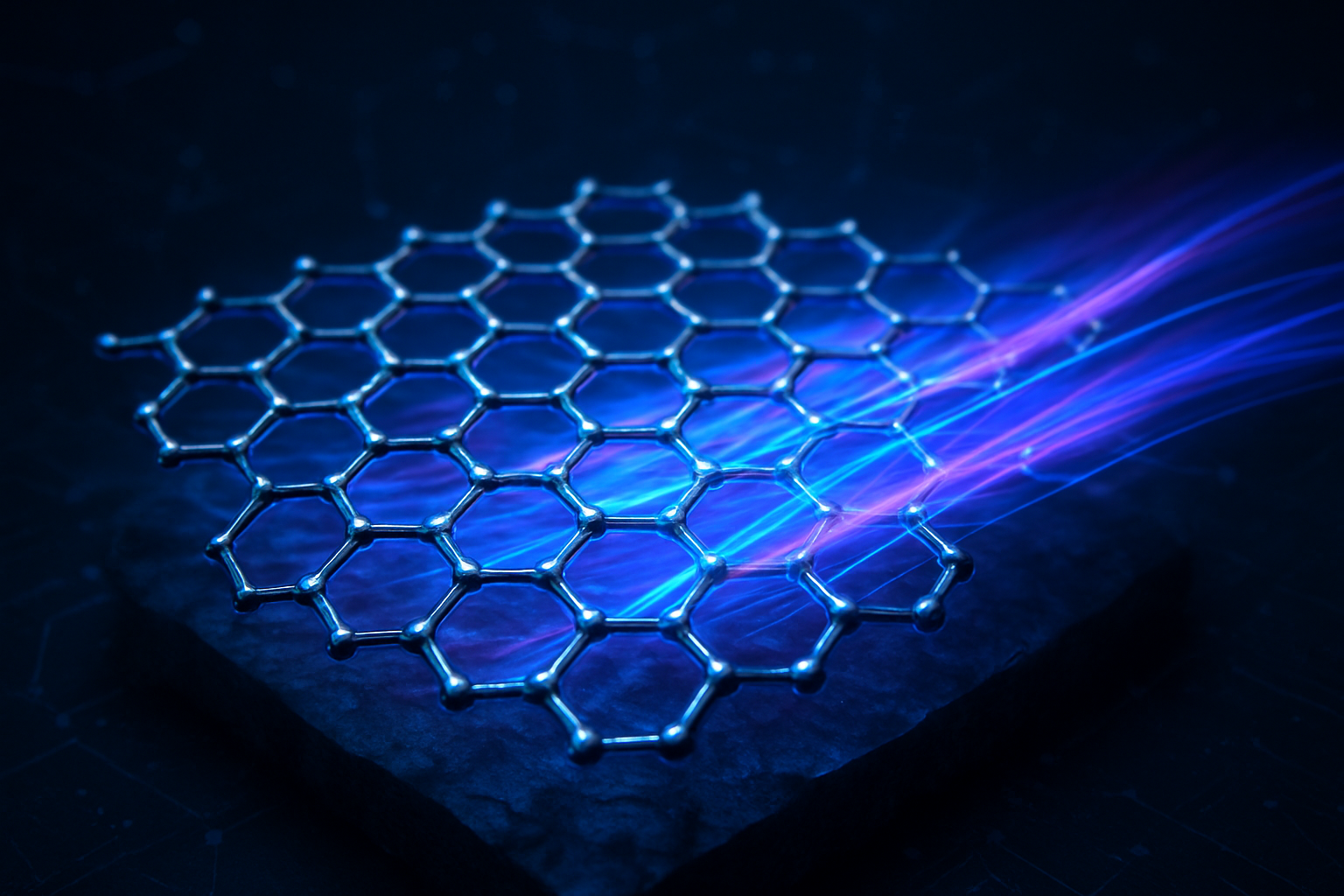

The technical hurdle that previously rendered graphene useless for digital logic was its lack of a "bandgap"—the ability for a material to switch between conducting and non-conducting states. Without a bandgap, transistors cannot create the "0s" and "1s" required for binary computing. The Georgia Tech team overcame this by developing epitaxial graphene, grown on silicon carbide (SiC) wafers using a proprietary process called Confinement Controlled Sublimation (CCS). By carefully heating SiC wafers, the researchers induced carbon atoms to form a "buffer layer" that chemically bonds to the substrate, naturally creating a semiconducting bandgap of 0.6 electron volts (eV) without degrading the material's inherent properties.

The performance specifications of this new material are staggering. The graphene semiconductor boasts an electron mobility of over 5,000 cm²/V·s—roughly ten times higher than silicon and twenty times higher than other emerging 2D materials like molybdenum disulfide. In practical terms, this high mobility means that electrons can travel through the material with much less resistance, allowing for switching speeds in the terahertz (THz) range. Furthermore, the team demonstrated a prototype field-effect transistor (FET) with an on/off ratio of 10,000:1, meeting the essential threshold for reliable digital logic gates.

Initial reactions from the research community have been transformative. While earlier attempts to create a bandgap involved "breaking" graphene by adding impurities or physical strain, de Heer’s method preserves the material's crystalline integrity. Experts at the 2025 International Electron Devices Meeting (IEDM) noted that this approach effectively "saves" graphene from the scrap heap of failed semiconductor candidates. By leveraging the existing supply chain for silicon carbide—already mature due to its use in electric vehicles—the Georgia Tech breakthrough provides a more viable manufacturing path than competing carbon nanotube or quantum dot technologies.

Industry Seismic Shifts: From Silicon Giants to Graphene Foundries

The commercial implications of functional graphene are already reshaping the strategic roadmaps of major semiconductor players. GlobalFoundries (NASDAQ: GFS) has emerged as an early leader in the race to commercialize this technology, entering into a pilot-phase partnership with Georgia Tech and the Department of Defense. The goal is to integrate graphene logic gates into "feature-rich" manufacturing nodes, specifically targeting AI hardware that requires extreme throughput. Similarly, NVIDIA (NASDAQ: NVDA), the current titan of AI computing, is reportedly exploring hybrid architectures where graphene co-processors handle ultra-fast data serialization, leaving traditional silicon to manage less intensive tasks.

The shift also creates a massive opportunity for material providers and equipment manufacturers. Companies like Wolfspeed (NYSE: WOLF) and onsemi (NASDAQ: ON), which specialize in silicon carbide substrates, are seeing a surge in demand as SiC becomes the "fertile soil" for graphene growth. Meanwhile, equipment makers such as Aixtron (XETRA: AIXA) and CVD Equipment Corp (NASDAQ: CVV) are developing specialized induction furnaces required for the CCS process. This move toward graphene-on-SiC is expected to disrupt the pure-play silicon dominance held by TSMC (NYSE: TSM), potentially allowing Western foundries to leapfrog current lithography limits by focusing on material-based performance gains rather than just shrinking transistor sizes.

Startups are also entering the fray, focusing on "Graphene-Native" AI accelerators. These companies aim to bypass the limitations of Von Neumann architecture by utilizing graphene’s unique properties for in-memory computing and neuromorphic designs. Because graphene can be stacked in atomic layers, it facilitates 3D Heterogeneous Integration (3DHI), allowing for chips that are physically smaller but computationally denser. This has put traditional chip designers on notice: the competitive advantage is shifting from those who can print the smallest lines to those who can master the most advanced materials.

A Sustainable Foundation for the AI Revolution

The broader significance of the graphene semiconductor lies in its potential to solve the AI industry’s "power wall." Current large language models and generative AI systems require tens of thousands of power-hungry H100 or Blackwell GPUs, leading to massive energy consumption and heat dissipation challenges. Graphene’s high mobility translates directly to lower operational voltage and reduced thermal output. By transitioning to graphene-based hardware, the energy cost of training a multi-trillion parameter model could be reduced by as much as 90%, making AI both more environmentally sustainable and economically viable for smaller enterprises.

However, the transition is not without concerns. The move toward a "post-silicon" landscape could exacerbate the digital divide, as the specialized equipment and intellectual property required for graphene manufacturing are currently concentrated in a few high-tech hubs. There are also geopolitical implications; as nations race to secure the supply chains for silicon carbide and high-purity graphite, we may see a new "Material Cold War" emerge. Critics also point out that while graphene is faster, the ecosystem for software and compilers designed for silicon’s characteristics will take years, if not a decade, to fully adapt to terahertz-scale computing.

Despite these hurdles, the graphene milestone is being compared to the transition from vacuum tubes to solid-state transistors. Just as the silicon transistor enabled the personal computer and the internet, the graphene semiconductor is viewed as the "enabling technology" for the next era of AI: real-time, high-fidelity edge intelligence and autonomous systems that require instantaneous processing without the latency of the cloud. This breakthrough effectively removes the "thermal ceiling" that has limited AI hardware performance since 2020.

The Road Ahead: 300mm Scaling and Terahertz Logic

The near-term focus for the Georgia Tech team and its industrial partners is the "300mm challenge." While graphene has been successfully grown on 100mm and 200mm wafers, the global semiconductor industry operates on 300mm (12-inch) standards. Scaling the CCS process to ensure uniform graphene quality across a 300mm surface is the primary bottleneck to mass production. Researchers predict that pilot 300mm graphene-on-SiC wafers will be demonstrated by late 2026, with low-volume production for specialized defense and aerospace applications following shortly after.

Long-term, we are looking at the birth of "Terahertz Computing." Current silicon chips struggle to exceed 5-6 GHz due to heat; graphene could push clock speeds into the hundreds of gigahertz or even low terahertz ranges. This would revolutionize fields beyond AI, including 6G and 7G telecommunications, real-time climate modeling, and molecular simulation for drug discovery. Experts predict that by 2030, we will see the first hybrid "Graphene-Inside" consumer devices, where high-speed communication and AI-processing modules are powered by graphene while the rest of the device remains silicon-based.

Challenges remain in perfecting the "Schottky barrier"—the interface between graphene and metal contacts. High resistance at these points can currently "choke" graphene’s speed. Solving this requires atomic-level precision in manufacturing, a task that DARPA’s Next Generation Microelectronics Manufacturing (NGMM) program is currently funding. As these engineering hurdles are cleared, the trajectory toward a graphene-dominated hardware landscape appears inevitable.

Conclusion: A Turning Point in Computing History

The creation of the first functional graphene semiconductor by Georgia Tech is more than just a scientific achievement; it is a fundamental reset of the technological landscape. By providing a 10x performance boost over silicon, this development ensures that the AI revolution will not be stalled by the physical limitations of 20th-century materials. The move from silicon to graphene represents the most significant transition in the history of electronics, offering a path to faster, cooler, and more efficient intelligence.

In the coming months, industry watchers should keep a close eye on progress in 300mm wafer uniformity and the first "tape-outs" of graphene-based logic gates from GlobalFoundries. While silicon will remain the workhorse of the electronics industry for years to come, its monopoly is officially over. We are witnessing the birth of a new epoch in computing—one where the limits are defined not by the size of the transistor, but by the extraordinary physics of the carbon atom.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.