In a milestone that signals the long-awaited transition of humanoid robotics from laboratory curiosities to industrial assets, Boston Dynamics and its parent company, Hyundai Motor Group (KRX: 005380), have officially launched field tests for the all-electric Atlas robot. This month, the robot began autonomous operations at the Hyundai Motor Group Metaplant America (HMGMA) in Ellabell, Georgia. Moving beyond the viral parkour videos of its predecessor, this new generation of Atlas is performing the "dull, dirty, and dangerous" work of a modern automotive factory, specifically tasked with sorting and sequencing heavy components in the plant’s warehouse.

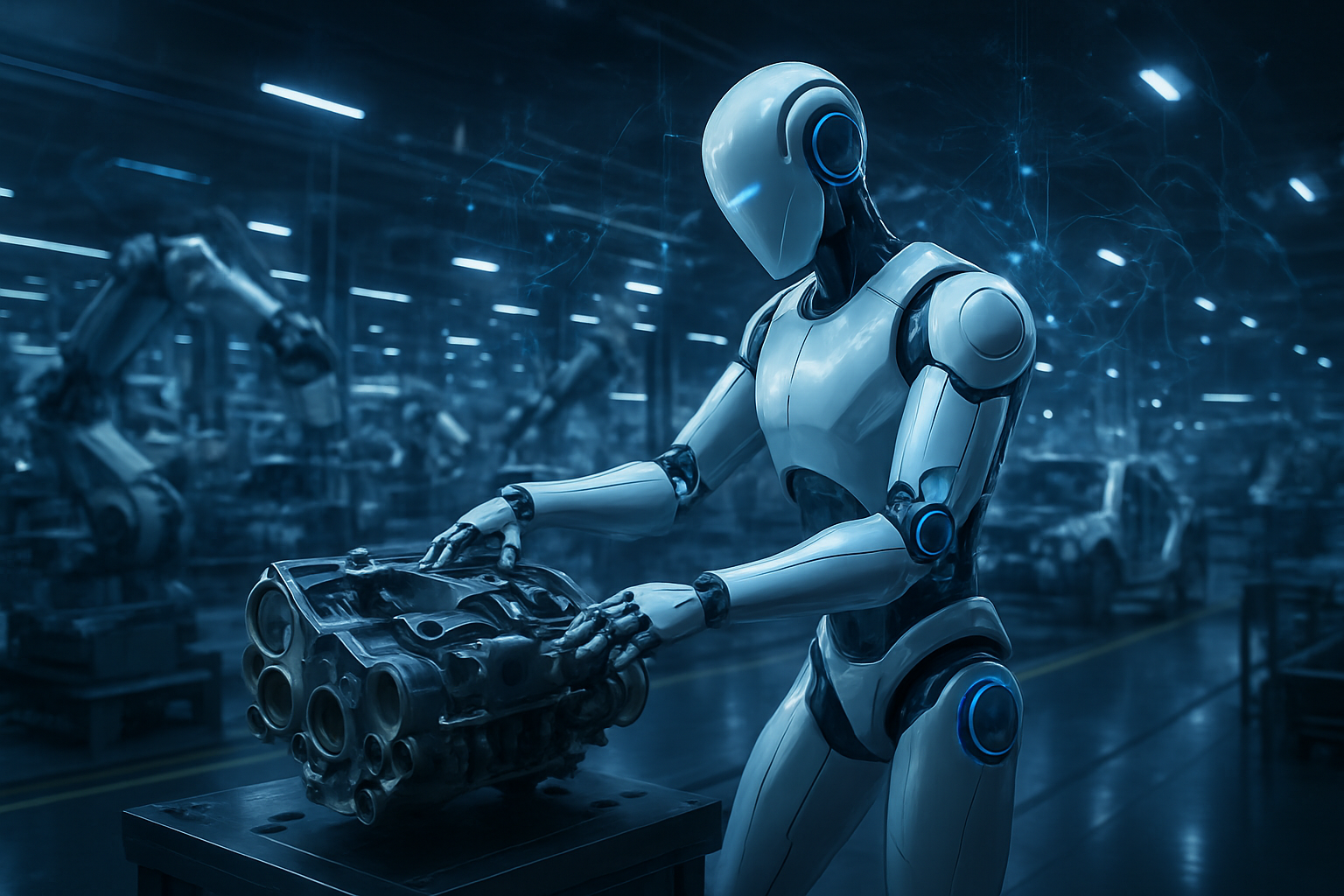

The deployment marks a pivotal moment for the robotics industry. While humanoid robots have long been promised as the future of labor, the integration of Atlas into a live manufacturing environment—operating without tethers or human remote control—demonstrates a new level of maturity in both hardware and AI orchestration. By leveraging advanced machine learning and a radically redesigned electric chassis, Atlas is now proving it can handle the physical variability of a factory floor, a feat that traditional stationary industrial robots have struggled to master.

Engineering the Industrial Humanoid

The technical evolution from the hydraulic Atlas to the 2026 electric production model represents a complete architectural overhaul. While the previous version relied on high-pressure hydraulics that were prone to leaks and required immense power, the new Atlas utilizes custom-designed, high-torque electric actuators. These allow for a staggering 56 degrees of freedom, including unique 360-degree rotating joints in the waist, head, and limbs. This "superhuman" range of motion enables the robot to turn in place and reach for components in cramped quarters without needing to reorient its entire body, a massive efficiency gain over human-constrained skeletal designs.

During the ongoing Georgia field tests, Atlas has been observed autonomously sequencing automotive roof racks—a task that requires identifying specific parts, navigating a shifting warehouse floor, and placing heavy items into precise slots for the assembly line. The robot boasts a sustained payload capacity of 66 lbs (30 kg), with the ability to burst-lift up to 110 lbs (50 kg). Unlike the scripted demonstrations of the past, the current Atlas utilizes an AI "brain" powered by Nvidia (NASDAQ: NVDA) hardware and vision models developed in collaboration with Google DeepMind, a subsidiary of Alphabet Inc. (NASDAQ: GOOGL). This allows the robot to adapt to environmental changes in real-time, such as a bin being moved or a human worker crossing its path.

Industry experts have been quick to note that this is not just a hardware test, but a trial of "embodied AI." Initial reactions from the robotics research community suggest that the most impressive feat is Atlas’s "end-to-end" learning capability. Rather than being programmed with every specific movement, the robot has been trained in simulation to understand the physics of the objects it handles. This allows it to manipulate irregular shapes and respond to slips or weight shifts with a fluidity that mirrors human reflexes, far surpassing the rigid movements seen in earlier humanoid iterations.

Strategic Implications for the Robotics Market

For Hyundai Motor Group, this deployment is a strategic masterstroke in its quest to build "Software-Defined Factories." By integrating Boston Dynamics’ technology directly into its $7.6 billion Georgia facility, Hyundai is positioning itself as a leader in the next generation of manufacturing. This move places immense pressure on competitors like Tesla (NASDAQ: TSLA), whose Optimus robot is also in early testing phases, and startups like Figure and Agility Robotics. Hyundai’s advantage lies in its "closed-loop" ecosystem: it owns the robot designer (Boston Dynamics), the AI infrastructure, and the massive manufacturing plants where the technology can be refined at scale.

The competitive implications extend beyond the automotive sector. Logistics giants and electronic manufacturers are watching the Georgia tests as a bellwether for the viability of general-purpose humanoids. If Atlas can reliably sort parts at HMGMA, it threatens to disrupt the market for specialized, single-task warehouse robots. Companies that can provide a "worker" that fits into human-centric infrastructure without needing expensive facility retrofits will hold a significant strategic advantage. Market analysts suggest that Hyundai’s goal of producing 30,000 humanoid units annually by 2028 is no longer a "moonshot" but a tangible production target.

A New Chapter in the Global AI Landscape

The shift of Atlas to the factory floor fits into a broader global trend of "embodied AI," where the intelligence of large language models is being wedded to physical machines. We are moving away from the era of "narrow AI"—which can only do one thing well—to "general-purpose robotics." This milestone is comparable to the introduction of the first industrial robotic arm in the 1960s, but with a crucial difference: the new generation of robots can see, learn, and adapt to the world around them.

However, the transition is not without concerns. While Hyundai emphasizes "human-centered automation"—using robots to take over ergonomically straining tasks like lifting heavy roof moldings—the long-term impact on the workforce remains a subject of intense debate. Labor advocates are monitoring the deployment closely, questioning how the "30,000 units by 2028" goal will affect the demand for entry-level industrial labor. Furthermore, as these robots become increasingly autonomous and integrated into cloud networks, cybersecurity and the potential for systemic failures in automated supply chains have become primary topics of discussion among tech policy experts.

The Roadmap to Full Autonomy

Looking ahead, the next 24 months will likely see Atlas expand its repertoire from simple sorting to complex component assembly. This will require even finer motor skills and more sophisticated tactile feedback in the robot's grippers. Near-term developments are expected to focus on multi-robot orchestration, where fleets of Atlas units communicate with each other and the plant's central management system to optimize the flow of materials in real-time.

Experts predict that by the end of 2026, we will see the first "robot-only" shifts in specific high-hazard areas of the Metaplant. The ultimate challenge remains the "99.9% reliability" threshold required for full-scale production. While Atlas has shown it can perform tasks in a field test, maintaining that performance over thousands of hours without technical intervention is the final hurdle. As the hardware becomes a commodity, the real battleground will move to the software—specifically, the ability to rapidly "teach" robots new tasks using generative AI and synthetic data.

Conclusion: From Laboratory to Industrial Reality

The deployment of the electric Atlas at Hyundai’s Georgia plant marks a definitive end to the era of robotics-as-entertainment. We have entered the era of robotics-as-infrastructure. By taking a humanoid out of the lab and putting it into the high-stakes environment of a billion-dollar automotive factory, Boston Dynamics and Hyundai have set a new benchmark for what is possible in the field of automation.

The key takeaway from this development is that the "brain" and the "body" of AI have finally caught up with each other. In the coming months, keep a close eye on the performance metrics coming out of HMGMA—specifically the "mean time between failures" and the speed of autonomous task acquisition. If these field tests continue to succeed, the sight of a humanoid robot walking the factory floor will soon move from a futuristic novelty to a standard feature of the global industrial landscape.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.