The venerable injection molding industry is experiencing a profound transformation, moving far beyond traditional manufacturing processes to embrace a future defined by intelligence, efficiency, and environmental responsibility. As of late 2024 and heading into 2025, a wave of technological advancements, strategic investments, and a relentless pursuit of sustainability are reshaping the landscape, propelling the global market towards an estimated USD 462.4 billion valuation by 2033. This evolution is marked by the deep integration of Industry 4.0 principles, a surge in advanced automation, and a critical pivot towards circular economy practices, signaling a new era for plastics and precision manufacturing worldwide.

This rapid expansion is not merely incremental; it represents a fundamental shift in how products are designed, produced, and brought to market. Companies are pouring resources into upgrading facilities, adopting cutting-edge machinery, and leveraging artificial intelligence to optimize every facet of the molding process. The immediate significance of these developments is clear: enhanced precision, reduced waste, accelerated production cycles, and the ability to meet increasingly complex demands for customized and high-performance components across diverse sectors, from medical devices to automotive and consumer electronics.

The Technological Crucible: AI, Automation, and Sustainable Materials Redefine Precision

The core of this revolution lies in the sophisticated integration of advanced technologies that are fundamentally altering the capabilities of injection molding. Specific details reveal a concerted effort to move towards highly intelligent and interconnected manufacturing ecosystems.

At the forefront is the pervasive adoption of Artificial Intelligence (AI) and Machine Learning (ML). These technologies are no longer theoretical concepts but practical tools revolutionizing operations. AI algorithms are now deployed to optimize critical process parameters in real-time, such as melt temperatures, injection speeds, and cooling times, ensuring consistent quality and maximizing throughput. Beyond process control, AI-powered vision systems are performing micron-level defect detection on thousands of parts per hour, drastically reducing scrap rates and improving overall product integrity. Furthermore, ML models are enabling predictive maintenance, anticipating equipment failures like screw barrel wear before they occur, thereby minimizing costly downtime and extending machine lifespan.

This digital transformation is intrinsically linked with Industry 4.0 and Smart Manufacturing paradigms. The integration of sensors, Internet of Things (IoT) devices, and cloud computing facilitates real-time data collection and analysis across the entire production line. This data fuels digital twins, virtual replicas of physical systems, allowing manufacturers to simulate mold behavior and part performance with unprecedented accuracy, significantly cutting prototyping costs and accelerating time-to-market. Smart supply chain integration, driven by AI-powered demand forecasting and enterprise resource planning (ERP) systems, further streamlines inventory management and production scheduling.

Simultaneously, Advanced Automation and Robotics are becoming indispensable. Collaborative robots (cobots) and traditional industrial robots are increasingly handling tasks such as part removal, intricate assembly, quality inspection, and packaging. This not only boosts accuracy and consistency but also addresses labor shortages and improves operational efficiency. For instance, C&J Industries' recent expansion (April 2025) included all-electric Toshiba molding presses coupled with automated 3-axis robots, demonstrating this trend in action for high-precision medical components.

Perhaps the most impactful shift is in Sustainability and Circular Economy Focus. Manufacturers are intensely focused on reducing their environmental footprint. This manifests in several ways:

- Material Innovation: A strong emphasis on bio-based and biodegradable polymers (e.g., PLA, PHA), recycled and recyclable materials, and advanced composites. Novel approaches are transforming ocean-sourced polymers and post-consumer PET into high-performance composites, even achieving HDPE-grade tensile strength with marine-degradable bioplastics.

- Energy Efficiency: The industry is rapidly transitioning from hydraulic to all-electric injection molding machines, a significant trend for 2025. These machines offer superior energy efficiency, eliminate the need for hydraulic oil, and boast a considerably lower carbon footprint.

- Waste Reduction: Implementation of closed-loop recycling systems to reintroduce scrap material back into the production cycle, minimizing waste and energy consumption.

- Lightweighting: The continuous demand for lighter parts, particularly in the automotive and aerospace sectors, drives innovation in materials and molding techniques to improve fuel efficiency and overall sustainability. Milacron's (NYSE: MCRN) eQ180, launched in October 2024, exemplifies this, designed specifically to produce multi-layer parts utilizing post-consumer recyclable (PCR) materials.

These advancements collectively represent a departure from previous approaches, moving away from reactive, manual processes towards proactive, data-driven, and highly automated manufacturing. Initial reactions from the AI research community and industry experts highlight the transformative potential, particularly in achieving unprecedented levels of precision, efficiency, and environmental compliance, which were previously unattainable with older technologies.

Competitive Landscape Reshaped: Who Benefits, Who Adapts

The seismic shifts in injection molding technology are having profound effects on the competitive landscape, creating clear winners and presenting strategic challenges for all players, from established tech giants to agile startups.

Companies that are aggressively investing in Industry 4.0 technologies, particularly AI and advanced automation, stand to benefit immensely. These include not only the injection molders themselves but also the suppliers of the underlying technology – automation specialists, software developers for manufacturing execution systems (MES), and material science innovators. For example, firms like Milacron Holdings Corp. (NYSE: MCRN), with its focus on all-electric machines and sustainable material processing, are well-positioned to capture market share driven by energy efficiency and green manufacturing mandates. Similarly, smaller, specialized molders like C&J Industries and Biomerics, by expanding into high-value segments like medical-grade cleanroom molding and metal injection molding (MIM) respectively, are carving out niches that demand high precision and specialized expertise.

The competitive implications for major AI labs and tech companies are significant, as their AI platforms and data analytics solutions become critical enablers for smart factories. Companies offering robust AI-driven predictive maintenance, quality control, and process optimization software will find a burgeoning market within the manufacturing sector. This extends to cloud providers whose infrastructure supports the massive data flows generated by connected molding machines.

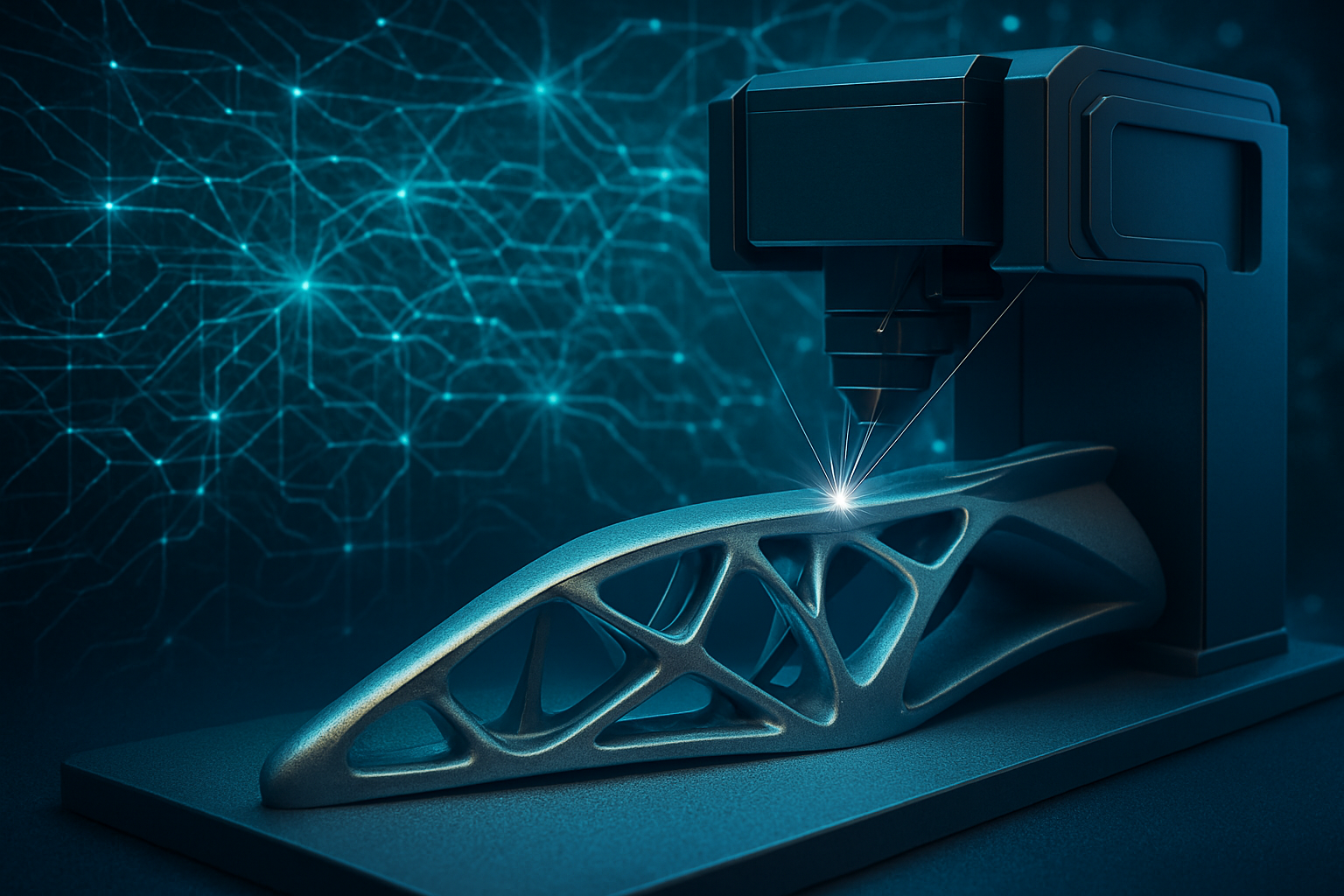

Potential disruption to existing products and services primarily impacts those relying on older, less efficient, or less sustainable molding techniques. Companies unable or unwilling to invest in modernization risk becoming obsolete. The demand for lightweight, multi-component, and customized parts also challenges traditional single-material, high-volume production models, favoring molders with flexible manufacturing capabilities and rapid prototyping expertise, often facilitated by 3D printing for tooling.

Market positioning is increasingly defined by technological prowess and sustainability credentials. Companies that can demonstrate a strong commitment to using recycled content, reducing energy consumption, and implementing closed-loop systems will gain a strategic advantage, especially as regulatory pressures and consumer demand for eco-friendly products intensify. The recent increase in M&A activities, such as Sunningdale Tech acquiring Proactive Plastics and Viant acquiring Knightsbridge Plastics, highlights a broader strategy to expand product portfolios, enter new regions (like the US market), and boost technological capabilities, signaling a consolidation and specialization within the industry to meet these evolving demands.

Broader Implications: Sustainability, Resilience, and the Future of Manufacturing

The transformation within injection molding is not an isolated phenomenon but a critical component of the broader manufacturing landscape's evolution, deeply intertwined with global trends in sustainability, supply chain resilience, and digital transformation.

This shift fits perfectly into the larger narrative of Industry 4.0 and the Smart Factory concept, where connectivity, data analytics, and automation converge to create highly efficient, adaptive, and intelligent production systems. Injection molding, as a foundational manufacturing process for countless products, is becoming a prime example of how traditional industries can leverage advanced technologies to achieve unprecedented levels of performance. The increasing adoption of AI, IoT, and digital twins within molding operations mirrors similar advancements across various manufacturing sectors, pushing the boundaries of what's possible in terms of precision and throughput.

The impacts are far-reaching. Economically, enhanced efficiency and reduced waste lead to significant cost savings, contributing to improved profitability for manufacturers. Environmentally, the move towards sustainable materials and energy-efficient machines directly addresses pressing global concerns about plastic pollution and carbon emissions. The push for lightweighting in industries like automotive and aerospace further amplifies these environmental benefits by reducing fuel consumption. Socially, the integration of robotics and AI is reshaping labor requirements, necessitating upskilling programs for workers to manage advanced systems, while also potentially creating new roles in data analysis and automation maintenance.

However, potential concerns also emerge. The upfront capital investment required for new, advanced machinery and software can be substantial, posing a barrier for smaller manufacturers. Cybersecurity risks associated with highly interconnected smart factories are another significant consideration, requiring robust protection measures. The ethical implications of AI in manufacturing, particularly concerning job displacement and decision-making autonomy, also warrant careful consideration and policy development.

Comparing this to previous manufacturing milestones, the current wave of innovation in injection molding rivals the introduction of automated assembly lines or the advent of computer numerical control (CNC) machining in its transformative potential. While those milestones focused on mechanization and precision, today's advancements center on intelligence and adaptability. This allows for a level of customization and responsiveness to market demands that was previously unimaginable, marking a significant leap forward in manufacturing capabilities and setting a new benchmark for industrial efficiency and sustainability.

The Horizon: What Comes Next for Injection Molding

Looking ahead, the injection molding industry is poised for continuous, rapid evolution, driven by ongoing research and development in materials science, AI, and automation. The near-term and long-term developments promise even more sophisticated and sustainable manufacturing solutions.

In the near term, we can expect to see further refinement and widespread adoption of existing trends. AI and ML algorithms will become even more sophisticated, offering predictive capabilities not just for maintenance but for anticipating market demand fluctuations and optimizing supply chain logistics with greater accuracy. The integration of advanced sensors will enable real-time material analysis during the molding process, allowing for instant adjustments to ensure consistent part quality, especially when working with varied recycled content. We will also see a continued surge in the development of novel bio-based and biodegradable polymers, moving beyond current limitations to offer comparable performance to traditional plastics in a wider range of applications. The demand for micro and multi-component molding will intensify, pushing the boundaries of miniaturization and functional integration for medical devices and advanced electronics.

Potential applications and use cases on the horizon are vast. Imagine self-optimizing molding machines that learn from every cycle, autonomously adjusting parameters for peak efficiency and zero defects. The widespread use of 3D-printed molds will enable true on-demand manufacturing for highly customized products, from personalized medical implants to bespoke consumer goods, at speeds and costs previously unattainable. In the automotive sector, advanced injection molding will facilitate the production of even lighter, more complex structural components for electric vehicles, further boosting their efficiency and range. The medical field will benefit from increasingly intricate and sterile molded components, enabling breakthroughs in diagnostics and surgical tools.

However, several challenges need to be addressed. The ongoing need for a skilled workforce capable of operating and maintaining these highly advanced systems is paramount. Educational institutions and industry players must collaborate to bridge this skills gap. The cost of implementing cutting-edge technologies remains a barrier for some, necessitating innovative financing models and government incentives. Furthermore, the standardization of data protocols and interoperability between different machines and software platforms will be crucial for seamless smart factory integration. The development of robust cybersecurity frameworks is also critical to protect proprietary data and prevent disruptions.

Experts predict that the industry will increasingly move towards a "lights-out" manufacturing model, where fully automated systems operate with minimal human intervention for extended periods. The focus will shift from simply making parts to intelligent, adaptive manufacturing ecosystems that can respond dynamically to global market changes and supply chain disruptions. The emphasis on circularity will also deepen, with a stronger push for designing products for disassembly and recycling from the outset, embedding sustainability into the very core of product development.

A New Chapter in Manufacturing Excellence

The current wave of innovation in injection molding technology and manufacturing marks a pivotal moment, ushering in an era of unprecedented efficiency, precision, and sustainability. The deep integration of artificial intelligence, advanced automation, and a commitment to circular economy principles are not just trends; they are fundamental shifts reshaping an industry vital to global production.

The key takeaways are clear: the future of injection molding is smart, green, and highly adaptive. Investments in all-electric machinery, AI-driven process optimization, and sustainable materials are driving significant improvements in energy efficiency, waste reduction, and product quality. The industry is also becoming more resilient, with nearshoring initiatives and strategic M&A activities bolstering supply chains and expanding capabilities. This evolution is enabling manufacturers to meet the growing demand for complex, customized, and environmentally responsible products across diverse sectors.

This development's significance in manufacturing history cannot be overstated. It represents a leap comparable to earlier industrial revolutions, transforming a traditional process into a high-tech, data-driven discipline. It underscores how foundational industries can leverage digital transformation to address contemporary challenges, from climate change to supply chain volatility. The ability to produce highly intricate parts with minimal waste, optimized by AI, sets a new benchmark for manufacturing excellence.

In the long term, the impact will be felt across economies and societies, fostering greater resource efficiency, enabling new product innovations, and potentially shifting global manufacturing footprints. What to watch for in the coming weeks and months includes further announcements of strategic investments in sustainable technologies, the emergence of more sophisticated AI-powered predictive analytics tools, and continued consolidation within the industry as companies seek to expand their technological capabilities and market reach. The journey towards a fully intelligent and sustainable injection molding industry is well underway, promising a future of smarter, cleaner, and more agile production.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.