Intel (NASDAQ:INTC) has officially reached a historic milestone in its quest to reclaim semiconductor leadership, announcing today the commencement of the pilot phase for its 14A (1.4nm) process node. This development comes as the company successfully completed rigorous acceptance testing for its fleet of ASML (NASDAQ:ASML) High-Numerical Aperture (High-NA) Extreme Ultraviolet (EUV) lithography machines at the D1X "Mod 3" facility in Oregon. CEO Lip-Bu Tan, who took the helm in early 2025, reaffirmed the company's unwavering commitment to the 14A roadmap, targeting high-volume manufacturing (HVM) by early 2027.

The transition to the "1.4nm era" represents the most significant technical pivot for Intel in over a decade. By being the first in the industry to move past the limitations of standard 0.33 NA EUV tools, Intel is positioning itself to leapfrog competitors who have hesitated to adopt the prohibitively expensive High-NA technology. The announcement has sent ripples through the tech sector, signaling that Intel’s "Foundry First" strategy is moving from a theoretical recovery plan to a tangible, high-performance reality that could reshape the global chip landscape.

Technical Mastery: RibbonFET 2 and the High-NA Breakthrough

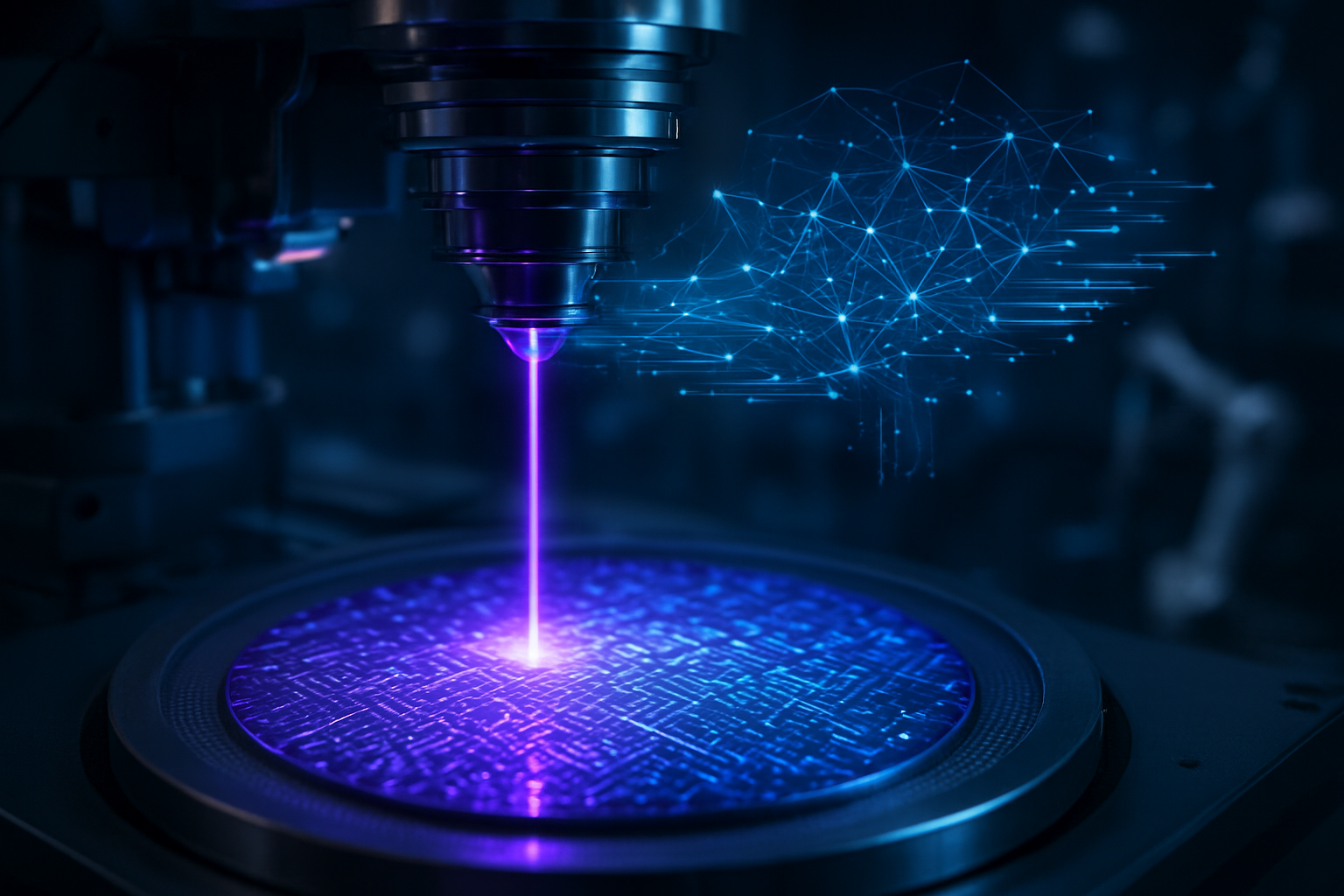

The 14A node is Intel’s first process built from the ground up to utilize the ASML Twinscan EXE:5200B, a $400 million machine capable of printing features with a resolution down to 8nm in a single pass. Technical data released today reveals that Intel has achieved a "field-stitching" overlay accuracy of 0.7nm at its Oregon pilot plant—a critical metric that confirms the viability of manufacturing massive AI GPUs and high-performance server chips on High-NA optics. Unlike the previous 18A node, which relied on complex multi-patterning with older EUV tools, 14A’s single-patterning approach significantly reduces defect density and shortens production cycle times.

Beyond the lithography, 14A introduces RibbonFET 2, Intel’s second-generation Gate-All-Around (GAA) transistor architecture. This is paired with PowerDirect, an evolution of the company’s industry-leading PowerVia backside power delivery system. By moving power routing to the back of the wafer and providing direct contact to the source and drain, Intel claims 14A will deliver a 15% to 20% improvement in performance-per-watt and a staggering 25% to 35% reduction in total power consumption compared to the 18A node.

Furthermore, the 14A node debuts "Turbo Cells"—specialized, double-height standard cells designed specifically for high-frequency AI logic. These cells allow for aggressive clock speeds in next-generation CPUs without the typical area or heat penalties associated with traditional scaling. Initial reactions from the silicon research community have been overwhelmingly positive, with analysts at SemiAnalysis noting that Intel’s mastery of High-NA's "field stitching" has effectively erased the technical lead long held by the world’s largest foundries.

Reshaping the Foundry Landscape: AWS and Microsoft Line Up

The strategic implications of the 14A progress are profound, particularly for Intel’s growing foundry business. Under CEO Lip-Bu Tan’s leadership, Intel has pivotally secured massive long-term commitments from "whale" customers like Amazon (NASDAQ:AMZN) and Microsoft (NASDAQ:MSFT). These hyperscalers are increasingly looking for domestic, leading-edge manufacturing alternatives to TSMC (NYSE:TSM) for their custom AI silicon. The 14A node is seen as the primary vehicle for these partnerships, offering a performance-density profile that TSMC may not match until its own A14 node debuts in late 2027 or 2028.

The competition is already reacting with aggressive capital maneuvers. TSMC recently announced a record-shattering $56 billion capital expenditure budget for 2026, largely aimed at accelerating its acquisition of High-NA tools to prevent Intel from establishing a permanent lithography lead. Meanwhile, Samsung (KRX:005930) has adopted a "dual-track" strategy, utilizing its early High-NA units to bolster both its logic foundry and its High Bandwidth Memory (HBM4) production. However, Intel’s early-mover advantage in calibrating these machines for high-volume logic gives them a strategic window that many analysts believe could last at least 12 to 18 months.

A Geopolitical and Technological Pivot Point

The success of the 14A node is about more than just transistor density; it is a vital component of the broader Western effort to re-shore critical technology. As the only company currently operating a calibrated High-NA fleet on U.S. soil, Intel has become the linchpin of the CHIPS Act’s long-term success. The ability to print 1.4nm features in Oregon—rather than relying on facilities in geopolitically sensitive regions—is a major selling point for defense contractors and government-aligned tech firms who require secure, domestic supply chains for the next generation of AI hardware.

This milestone also serves as a definitive answer to the recurring question: "Is Moore’s Law dead?" By successfully integrating High-NA EUV, Intel is proving that the physical limits of silicon can still be pushed through extreme engineering. The jump from 18A to 14A is being compared to the transition from "Planar" to "FinFET" transistors a decade ago—a fundamental shift in how chips are designed and manufactured. While concerns remain regarding the astronomical cost of these tools and the resulting price-per-wafer, the industry consensus is shifting toward the belief that those who own the "High-NA frontier" will own the AI era.

The Road Ahead: 14A-P, 14A-E, and the 10A Horizon

Looking forward, Intel is not resting on the 14A pilot. The company has already detailed two future iterations: 14A-P (Performance) and 14A-E (Efficiency). These variants, slated for 2028, will refine the RibbonFET 2 architecture to target specific niches, such as ultra-low-power edge AI devices and massive, liquid-cooled data center processors. Beyond that, the company is already conducting early R&D on the 10A (1nm) node, which experts predict will require even more exotic materials like 2D transition metal dichalcogenides (TMDs) to maintain scaling.

The primary challenge remaining for Intel is yield maturity. While the technical "acceptance" of the High-NA tools is complete, the company must now prove it can maintain consistently high yields across millions of units to remain competitive with TSMC’s legendary efficiency. Experts predict that the next six months will be dedicated to "recipe tuning," where Intel engineers will work to optimize the interaction between the new High-NA light source and the photoresists required for such extreme resolutions.

Summary: Intel’s New Chapter

Intel's entry into the 14A pilot phase and the successful validation of High-NA EUV mark a turning point for the iconic American chipmaker. By achieving 0.7nm overlay accuracy and confirming a 2027 HVM timeline, Intel has effectively validated the "Angstrom Era" roadmap that many skeptics once viewed as overly ambitious. The leadership of Lip-Bu Tan has successfully stabilized the company's execution, shifting the focus from missing deadlines to setting the industry pace.

This development is perhaps the most significant in Intel’s history since the introduction of the Core architecture. In the coming weeks, the industry will be watching for further customer announcements, particularly whether NVIDIA (NASDAQ:NVDA) or Apple (NASDAQ:AAPL) will reserve capacity on the 14A line. For now, the message is clear: the race for the 1nm threshold is on, and for the first time in years, Intel is leading the pack.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.