As the artificial intelligence revolution enters a new era of localized hardware production, Micron Technology (NASDAQ: MU) is set to officially break ground this week on its massive $100 billion semiconductor manufacturing complex in Clay, New York. Scheduled for January 16, 2026, the ceremony marks a definitive turning point in the United States' decades-long effort to reshore critical technology manufacturing. The mega-fab, the largest private investment in New York State’s history, is positioned as the primary engine for domestic high-performance memory production, specifically designed to feed the insatiable demand of the AI era.

The groundbreaking follows a rigorous multi-year environmental and regulatory review process that delayed the initial construction timeline but solidified the project’s scope. With over 20,000 pages of environmental impact studies behind them, Micron and federal officials are moving forward with a project that promises to create nearly 50,000 jobs and secure the "brains" of the AI hardware stack—High Bandwidth Memory (HBM)—on American soil. This development comes at a critical juncture as cloud providers and AI labs increasingly prioritize supply chain resilience over the sheer speed of global logistics.

The Vanguard of Memory: HBM4 and the 1-Gamma Frontier

The New York mega-fab is not merely a production site; it is a technical fortress designed to manufacture the world’s most advanced memory nodes. At the heart of the Clay facility’s roadmap is the production of HBM4 and its successors. High Bandwidth Memory is the essential "gasoline" for AI accelerators, allowing data to move between the memory and the processor at speeds that conventional DRAM cannot achieve. By stacking DRAM layers vertically using advanced packaging techniques, Micron’s upcoming HBM4 stacks are expected to deliver massive throughput while consuming up to 30% less power than current market alternatives.

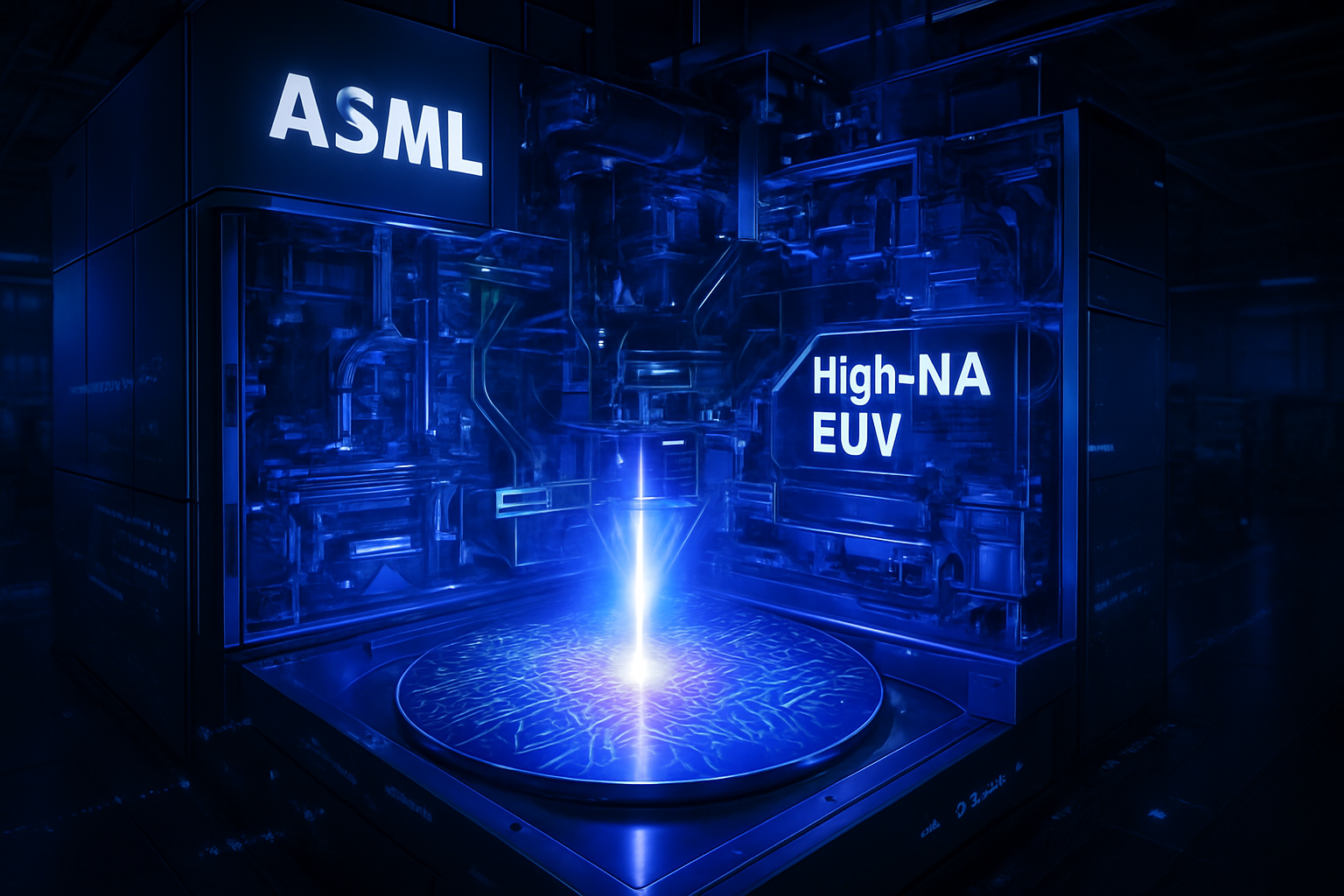

Technically, the site will utilize Micron’s proprietary 1-gamma (1γ) process node. This node is a significant leap from current technologies, as it fully integrates extreme ultraviolet (EUV) lithography into the mass-production flow. Unlike previous generations that relied on multi-patterning with deep ultraviolet (DUV) light, the 1-gamma process allows for finer circuitry and higher density, which is paramount for the massive parameter counts of 2026-era Large Language Models (LLMs). Analysts from KeyBanc (NYSE: KEY) have noted that Micron’s technical leadership in power efficiency is already making it a preferred partner for the next generation of power-constrained AI data centers.

Initial industry reactions have been overwhelmingly positive, though pragmatic regarding the timeline. While wafer production in New York is not expected to reach full volume until 2030, the facility's design—featuring four separate fab modules each with 600,000 square feet of cleanroom space—has been hailed by the AI research community as a "generational asset." Experts argue that the integration of research and development from the nearby Albany NanoTech Complex with the mass production in Clay creates a "Silicon Corridor" that could rival the manufacturing clusters of East Asia.

Reshaping the Competitive Landscape: NVIDIA and the HBM Rivalry

The strategic implications for AI hardware giants are profound. NVIDIA (NASDAQ: NVDA), which currently dominates the AI GPU market, stands as the most significant indirect beneficiary of the New York mega-fab. CEO Jensen Huang has publicly endorsed the project, noting that domestic HBM production is a vital safeguard against geopolitical bottlenecks. As NVIDIA shifts toward its "Rubin" GPU architecture and beyond, the availability of a stable, U.S.-based memory supply reduces the risk of the supply-chain "whiplash" that plagued the industry during the early 2020s.

Competitive pressure is also mounting on Micron’s primary rivals, SK Hynix and Samsung (KRX: 005930). While SK Hynix currently holds the largest share of the HBM market, Micron’s aggressive move into New York—supported by billions in federal subsidies—is seen as a direct challenge to South Korean dominance. By early 2026, Micron has already clawed back a 21% share of the HBM market through its facilities in Idaho and Taiwan; the New York site is the long-term play to push that share toward 40%. Advanced Micro Devices (NASDAQ: AMD) is also expected to leverage Micron’s domestic capacity for its future Instinct MI-series accelerators, ensuring that no single GPU manufacturer has a monopoly on U.S.-made memory.

For startups and smaller AI labs, the long-term impact will be felt in the stabilization of hardware costs. The persistent "AI chip shortage" of previous years was often a memory shortage in disguise. By increasing global HBM capacity by such a significant margin, Micron effectively lowers the barrier to entry for firms requiring high-density compute power. Market positioning is shifting; "Made in USA" is no longer just a political slogan but a premium technical requirement for Western government and enterprise AI contracts.

The Geopolitical Anchor: CHIPS Act and Economic Sovereignty

The groundbreaking is a crowning achievement for the CHIPS and Science Act, which provided the financial bedrock for the project. Micron has finalized a direct funding agreement with the U.S. Department of Commerce for $6.14 billion in federal grants, with approximately $4.6 billion earmarked specifically for the first two phases in Clay. This is bolstered by an additional $5.5 billion in "GREEN CHIPS" tax credits from New York State, contingent on the facility operating on 100% renewable energy and achieving LEED Gold certification.

This project represents more than just a corporate expansion; it is a move toward "AI Sovereignty." In the current geopolitical climate of 2026, the ability to manufacture the fundamental components of artificial intelligence within domestic borders is seen as a national security imperative. The CHIPS Act funding comes with stringent "clawback" provisions that prevent Micron from expanding high-end manufacturing in "countries of concern," effectively tethering the company’s future to the Western economic bloc.

However, the path has not been without concerns. Some economists point to the "windfall profit-sharing" requirements and the mandate for affordable childcare as potential burdens on the project’s profitability. Furthermore, the delay in the production start date to 2030 has led some to question if the U.S. can move fast enough to keep pace with the hyper-accelerated AI development cycle. Nevertheless, the consensus among policy experts is that a 20-year investment in New York is the only way to break the current reliance on highly concentrated manufacturing hubs in sensitive regions of the Pacific.

The Road to 2030: Future Developments and Challenges

Looking ahead, the next several years will be a period of intense infrastructure development. While the New York site prepares for its first wafer in 2030, Micron is accelerating its Boise, Idaho facility to bridge the capacity gap, with that site expected to come online in 2027. This two-pronged approach ensures that Micron remains competitive in the HBM4 and HBM5 cycles while the New York mega-fab prepares for the era of HBM6 and beyond.

The primary challenges remaining are labor and logistics. The construction of a project of this scale requires a specialized workforce that currently exceeds the capacity of the regional labor market. To address this, Micron has partnered with local universities and trade unions to create the "Northwest-Northeast Memory Corridor," a talent pipeline designed to train thousands of semiconductor technicians and engineers.

Experts predict that by the time the first New York fab is fully operational in 2030, the AI landscape will have shifted from Large Language Models to "Agentic AI" systems that require even more persistent and high-speed memory. The Clay facility is being built with "future-proofing" in mind, including flexible cleanroom layouts that can accommodate the next generation of lithography beyond EUV, potentially including High-NA (Numerical Aperture) EUV systems.

A New Era for American Silicon

The groundbreaking of the Micron New York mega-fab is a historic milestone that marks the beginning of the end for the United States' total reliance on offshore memory manufacturing. By committing $100 billion over the next two decades, Micron is betting on a future where AI is the primary driver of global GDP and where the physical location of hardware production is a strategic asset of the highest order.

As we move toward the 2030s, the significance of this project will likely be compared to the founding of Silicon Valley or the industrial mobilization of the mid-20th century. It represents a rare alignment of corporate ambition, state-level incentive, and federal national security policy. While the 2030 production date feels distant, the infrastructure being laid this week in Clay, New York, is the foundation upon which the next generation of artificial intelligence will be built.

Investors and industry watchers should keep a close eye on Micron’s quarterly progress reports throughout 2026, as the company navigates the complexities of the largest construction project in the industry’s history. For now, the message from Clay is clear: the AI memory race has a new home in the United States.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.