In a definitive signal that the artificial intelligence infrastructure boom is far from over, Micron Technology (NASDAQ: MU) has delivered a fiscal first-quarter 2026 earnings report that has sent shockwaves through the semiconductor industry. Reporting a staggering $13.64 billion in revenue—a 57% year-over-year increase—Micron has not only beaten analyst expectations but has fundamentally redefined the market's understanding of the "AI Memory Supercycle." The company's guidance for the second quarter was even more audacious, projecting revenue of $18.7 billion, a figure that implies a massive 132% growth compared to the previous year.

The significance of these numbers cannot be overstated. As of late December 2025, it has become clear that memory is no longer a peripheral component of the AI stack; it is the fundamental "oxygen" that allows AI accelerators to breathe. Micron’s announcement that its High Bandwidth Memory (HBM) capacity for the entire 2026 calendar year is already sold out highlights a critical bottleneck in the global AI supply chain. With major hyperscalers locked into long-term agreements, the industry is entering an era where the ability to compute is strictly governed by the ability to store and move data at lightning speeds.

The Technical Evolution: From HBM3E to the HBM4 Frontier

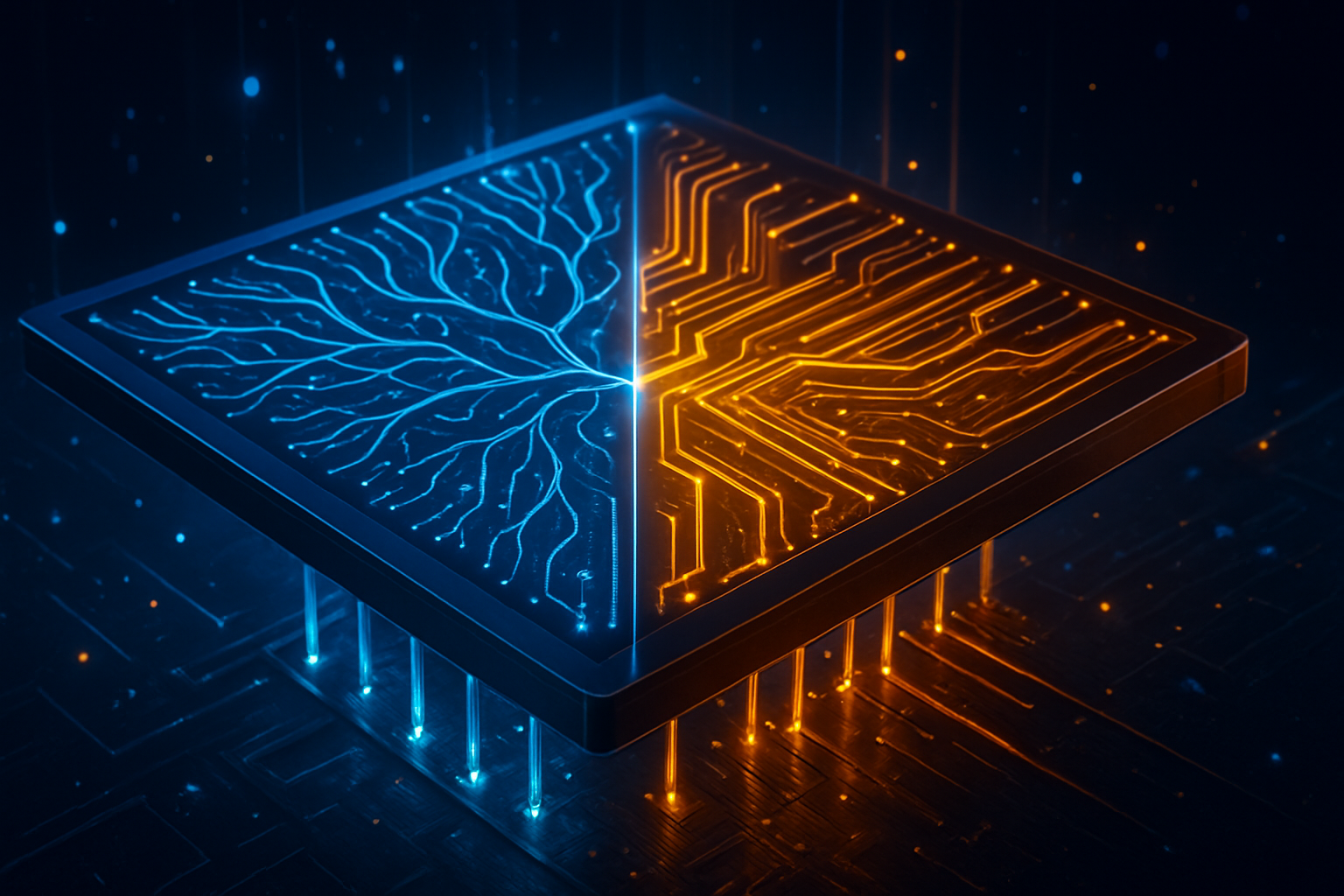

The technical drivers behind Micron’s record-breaking quarter lie in the rapid adoption of HBM3E and the impending transition to HBM4. High Bandwidth Memory is uniquely engineered to provide the massive data throughput required by modern Large Language Models (LLMs). Unlike traditional DDR5 memory, HBM stacks DRAM dies vertically and connects them directly to the processor using a silicon interposer. Micron’s current HBM3E 12-high stacks offer industry-leading power efficiency and bandwidth, but the demand has already outpaced the company’s ability to manufacture them.

The manufacturing process for HBM is notoriously "wafer-intensive." For every bit of HBM produced, approximately three bits of standard DRAM capacity are lost due to the complexity of the stacking and through-silicon via (TSV) processes. This "capacity asymmetry" is a primary reason for the persistent supply crunch. Furthermore, AI servers now require six to eight times more DRAM than conventional enterprise servers, creating a multiplier effect on demand that the industry has never seen before.

Looking ahead, the shift toward HBM4 is slated for mid-2026. This next generation of memory is expected to offer bandwidth exceeding 2.0 TB/s per stack—a 60% improvement over HBM3E—while utilizing a 12nm logic process. This transition represents a significant architectural shift, as HBM4 will increasingly blur the lines between memory and logic, allowing for even tighter integration with next-generation AI accelerators.

A New Competitive Landscape for Tech Giants

The "sold out" status of Micron’s 2026 capacity creates a complex strategic environment for the world’s largest tech companies. NVIDIA (NASDAQ: NVDA), Meta Platforms (NASDAQ: META), and Microsoft (NASDAQ: MSFT) are currently in a high-stakes race to secure enough HBM to power their upcoming data center expansions. Because Micron can currently only fulfill about half to two-thirds of the requirements for some of its largest customers, these tech giants are forced to navigate a "scarcity economy" for silicon.

For NVIDIA, Micron’s roadmap is particularly vital. Micron has already begun sampling its 36GB HBM4 modules, which are positioned as the primary memory solution for NVIDIA’s upcoming Vera Rubin AI architecture. This partnership gives Micron a strategic advantage over competitors like SK Hynix and Samsung, as it solidifies its role as a preferred supplier for the most advanced AI chips on the planet.

Meanwhile, startups and smaller AI labs may find themselves at a disadvantage. As the "big three" memory producers (Micron, SK Hynix, and Samsung) prioritize high-margin HBM for hyperscalers, the availability of standard DRAM for other sectors could tighten, driving up costs across the entire electronics industry. This market positioning has led analysts at JPMorgan Chase (NYSE: JPM) and Morgan Stanley (NYSE: MS) to suggest that "Memory is the New Compute," shifting the power dynamics of the semiconductor sector.

The Structural Shift: Why This Cycle is Different

The term "AI Memory Supercycle" describes a structural shift in the industry rather than a typical boom-and-bust commodity cycle. Historically, the memory market has been plagued by volatility, with periods of oversupply leading to price crashes. However, the current environment is driven by multi-year infrastructure build-outs that are less sensitive to consumer spending and more tied to the fundamental race for AGI (Artificial General Intelligence).

The wider significance of Micron's $13.64 billion quarter is the realization that the Total Addressable Market (TAM) for HBM is expanding much faster than anticipated. Micron now expects the HBM market to reach $100 billion by 2028, a milestone previously not expected until 2030 or later. This accelerated timeline suggests that the integration of AI into every facet of enterprise software and consumer technology is happening at a breakneck pace.

However, this growth is not without concerns. The extreme capital intensity required to build new fabs—Micron has raised its FY2026 CapEx to $20 billion—means that the barrier to entry is higher than ever. There are also potential risks regarding the geographic concentration of manufacturing, though Micron’s expansion into Idaho and Syracuse, New York, supported by the CHIPS Act, provides a degree of domestic supply chain security that is increasingly valuable in the current geopolitical climate.

Future Horizons: The Road to Mid-2026 and Beyond

As we look toward the middle of 2026, the primary focus will be the mass production ramp of HBM4. This transition will be the most significant technical hurdle for the industry in years, as it requires moving to more advanced logic processes and potentially adopting "base die" customization where the memory is tailored specifically for the processor it sits next to.

Beyond HBM, we are likely to see the emergence of new memory architectures like CXL (Compute Express Link), which allows for memory pooling across data centers. This could help alleviate some of the supply pressures by allowing for more efficient use of existing resources. Experts predict that the next eighteen months will be defined by "co-engineering," where memory manufacturers like Micron work hand-in-hand with chip designers from the earliest stages of development.

The challenge for Micron will be executing its massive capacity expansion without falling into the traps of the past. Building the Syracuse and Idaho fabs is a multi-year endeavor that must perfectly time the market's needs. If AI demand remains on its current trajectory, even these massive investments may only barely keep pace with the world's hunger for data.

Final Reflections on a Watershed Moment

Micron’s fiscal Q1 2026 results represent a watershed moment in AI history. By shattering revenue records and guiding for an even more explosive Q2, the company has proved that the AI revolution is as much about the "bits" of memory as it is about the "flops" of processing power. The fact that 2026 capacity is already spoken for is the ultimate validation of the AI Memory Supercycle.

For investors and industry observers, the key takeaway is that the bottleneck for AI progress has shifted. While GPU availability was the story of 2024 and 2025, the narrative of 2026 will be defined by HBM supply. Micron has successfully transformed itself from a cyclical commodity producer into a high-tech cornerstone of the global AI economy.

In the coming weeks, all eyes will be on how competitors respond and whether the supply chain can keep up with the $18.7 billion quarterly demand Micron has forecasted. One thing is certain: the era of "Memory as the New Compute" has officially arrived, and Micron Technology is leading the charge.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.