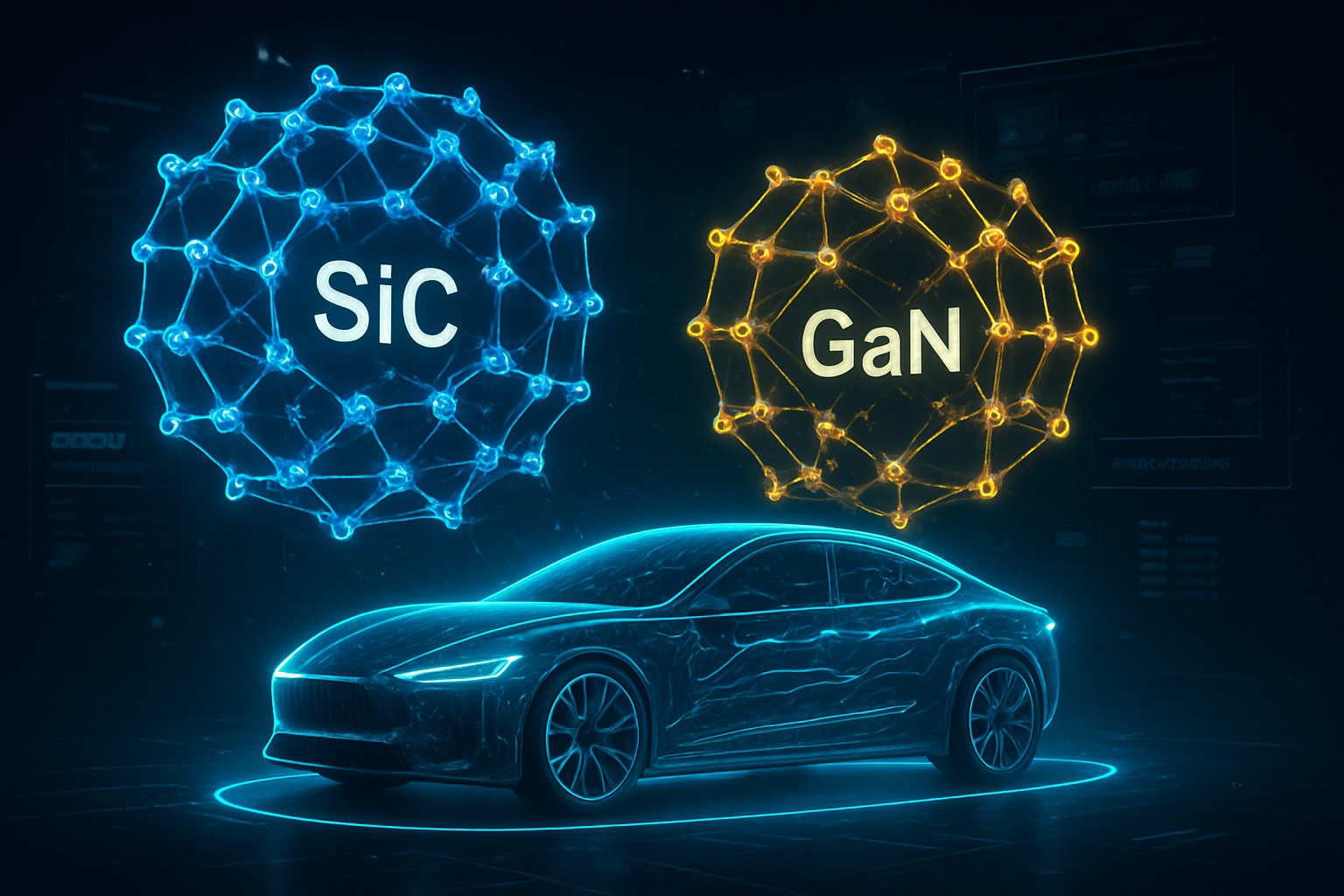

The global transition toward fully autonomous, software-defined vehicles has hit a critical bottleneck: the "power wall." As next-generation automotive AI systems demand unprecedented levels of compute, the energy required to fuel these "digital brains" is threatening to cannibalize the driving range of electric vehicles (EVs). In a landmark move to bridge this gap, Tata Electronics and ROHM Co., Ltd. (TYO: 6963) announced a strategic partnership in late December 2025 to mass-produce Silicon Carbide (SiC) semiconductors. This collaboration is set to become the bedrock of the "Automotive AI" revolution, providing the high-efficiency power foundation necessary for the fast-charging EVs and high-performance AI processors of tomorrow.

The significance of this partnership, finalized on December 22, 2025, extends far beyond simple component manufacturing. By combining the massive industrial scale of the Tata Group with the advanced wide-bandgap (WBG) expertise of ROHM, the alliance aims to localize a complete semiconductor ecosystem in India. This move is specifically designed to support the 800V electrical architectures required by high-end autonomous platforms, ensuring that the heavy energy draw of AI inference does not compromise vehicle performance or charging speeds.

The SiC Advantage: Enabling the AI "Brain"

At the heart of this development is Silicon Carbide (SiC), a wide-bandgap material that is rapidly replacing traditional silicon in high-performance power electronics. Unlike standard silicon, SiC can handle significantly higher voltages and temperatures while reducing energy loss by up to 50%. In the context of an EV, this efficiency translates into a 10% increase in driving range or the ability to use smaller, lighter battery packs. However, for the AI research community, the most critical aspect of SiC is its ability to support the massive power requirements of high-performance compute modules like the NVIDIA (NASDAQ: NVDA) DRIVE Thor or Qualcomm (NASDAQ: QCOM) Snapdragon Ride platforms.

These AI "brains" can consume upwards of 500W to 1,000W to process the petabytes of data coming from LiDAR, Radar, and high-resolution cameras. Traditional silicon power systems often struggle with the thermal management and stable voltage regulation required by these chips, leading to "thermal throttling" where the AI must slow down to prevent overheating. The Tata-ROHM SiC modules solve this by offering three times the thermal conductivity of silicon, allowing AI processors to run at peak performance for longer durations. This technical leap enables Level 3 and Level 4 autonomous maneuvers to be executed with higher precision and lower latency, as the underlying power delivery system remains stable even under extreme computational loads.

Strategic Realignment in the Global EV Market

The partnership places the Tata Group at the center of the global semiconductor and automotive supply chains. Tata Motors (NSE: TATAMOTORS) and its luxury subsidiary, Jaguar Land Rover (JLR), are poised to be the primary beneficiaries, integrating these SiC components into their upcoming 2026 vehicle lineups. This strategic move directly challenges the dominance of Tesla (NASDAQ: TSLA), which was an early adopter of SiC technology but now faces a more crowded and technologically advanced field. By securing a localized supply of SiC, Tata reduces its dependence on external foundries and insulates itself from the geopolitical volatility that has plagued the chip industry in recent years.

For ROHM (TYO: 6963), the deal provides a massive manufacturing partner and a gateway into the burgeoning Indian EV market, which is projected to grow exponentially through 2030. The collaboration also disrupts the existing market positioning of traditional Tier-1 suppliers. As Tata Electronics builds out its $11 billion fabrication plant in Dholera, Gujarat, in partnership with PSMC, the company is evolving from a consumer electronics manufacturer into a vertically integrated powerhouse capable of producing everything from the AI software to the power semiconductors that run it. This level of integration is a strategic advantage that few companies, other than perhaps BYD or Tesla, currently possess.

A New Era of Hardware-Optimized AI

The Tata-ROHM alliance reflects a broader shift in the AI landscape: the transition from "software-defined" to "hardware-optimized" intelligence. For years, the focus of the AI industry was on training larger models; now, the focus has shifted to the "edge"—the physical hardware that must run these models in real-time in the real world. In the automotive sector, this means that the physical properties of the semiconductor—its bandgap, its thermal resistance, and its switching speed—are now as important as the neural network architecture itself.

This development also carries significant geopolitical weight. India’s Semiconductor Mission is no longer just a policy goal; with the Dholera "Fab" and the ROHM partnership, it is becoming a tangible reality. By focusing on SiC and wide-bandgap materials, India is skipping the legacy silicon competition and moving straight to the cutting-edge materials that will define the next decade of green technology. While concerns remain regarding the massive water and energy requirements of such fabrication plants, the potential for India to become a "plus-one" to Taiwan and Japan in the global chip supply chain is a milestone that mirrors the early breakthroughs in the global software industry.

The Roadmap to 2027 and Beyond

Looking ahead, the near-term roadmap for this partnership is aggressive. Mass production of the first automotive-grade MOSFETs is expected to begin in 2026 at Tata’s assembly and test facility in Assam, with pilot production of SiC wafers at the Dholera plant scheduled for 2027. These components will be integral to Tata Motors’ newly unveiled "T.idal" architecture—a software-defined vehicle platform showcased at CES 2026 that centralizes all compute functions into a single, SiC-powered "super-brain."

Future applications extend beyond just passenger cars. The high-density power management offered by SiC is a prerequisite for the next generation of electric vertical take-off and notation (eVTOL) aircraft and autonomous heavy-duty trucking. Experts predict that as SiC costs continue to fall due to the scale provided by the Tata-ROHM partnership, we will see a "democratization" of high-performance AI in vehicles, moving advanced ADAS features from luxury models into entry-level commuter cars. The primary challenge remains the yield rates of SiC wafer production, which are notoriously difficult to master, but the combined expertise of ROHM and PSMC provides a strong technical foundation to overcome these hurdles.

Summary of the Automotive AI Shift

The partnership between Tata Electronics and ROHM marks a pivotal moment in the history of automotive technology. It represents the successful convergence of power electronics and artificial intelligence, solving the "power wall" that has long hindered the deployment of high-performance autonomous systems. Key takeaways from this development include:

- Energy Efficiency: SiC enables a 10% range boost and 50% faster charging, freeing up the "power budget" for AI compute.

- Vertical Integration: Tata Motors (NSE: TATAMOTORS) is securing its future by controlling the semiconductor supply chain from fabrication to the vehicle floor.

- Geopolitical Shift: India is emerging as a critical hub for next-generation wide-bandgap semiconductors, challenging established players.

As we move into 2026, the industry will be watching the Dholera facility closely. The successful rollout of the first batch of "Made in India" SiC chips will not only validate Tata’s $11 billion bet but will also signal the start of a new era where the intelligence of a vehicle is limited only by the efficiency of the materials powering it.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.