As the new administration enters its second year, a series of aggressive trade maneuvers has sent shockwaves through the global technology sector. On January 13, 2026, the White House codified a landmark "U.S. Detour" protocol for high-performance AI semiconductors, fundamentally altering how companies like Nvidia (NASDAQ:NVDA) and AMD (NASDAQ:AMD) access the Chinese market. This policy shift, characterized by a transition from broad Biden-era prohibitions to a "monetized export" model, effectively forces advanced chips manufactured abroad to route through U.S. soil for mandatory laboratory verification before they can be shipped to restricted destinations.

The announcement was followed just 24 hours later by a sweeping executive proclamation targeting the "upstream" supply chain. President Trump has established a strict 180-day deadline—falling on July 13, 2026—for the United States to secure binding agreements with global allies to diversify away from Chinese-processed critical minerals. If these negotiations fail to yield a non-Chinese supply chain for the rare earth elements essential to AI hardware, the administration is authorized to impose unilateral "remedial" tariffs and minimum import prices. Together, these moves represent a massive escalation in the geopolitical struggle for AI supremacy, framed within the industry as a definitive realization of "Item 23" on the global risk index: Supply Chain Trade Impacts.

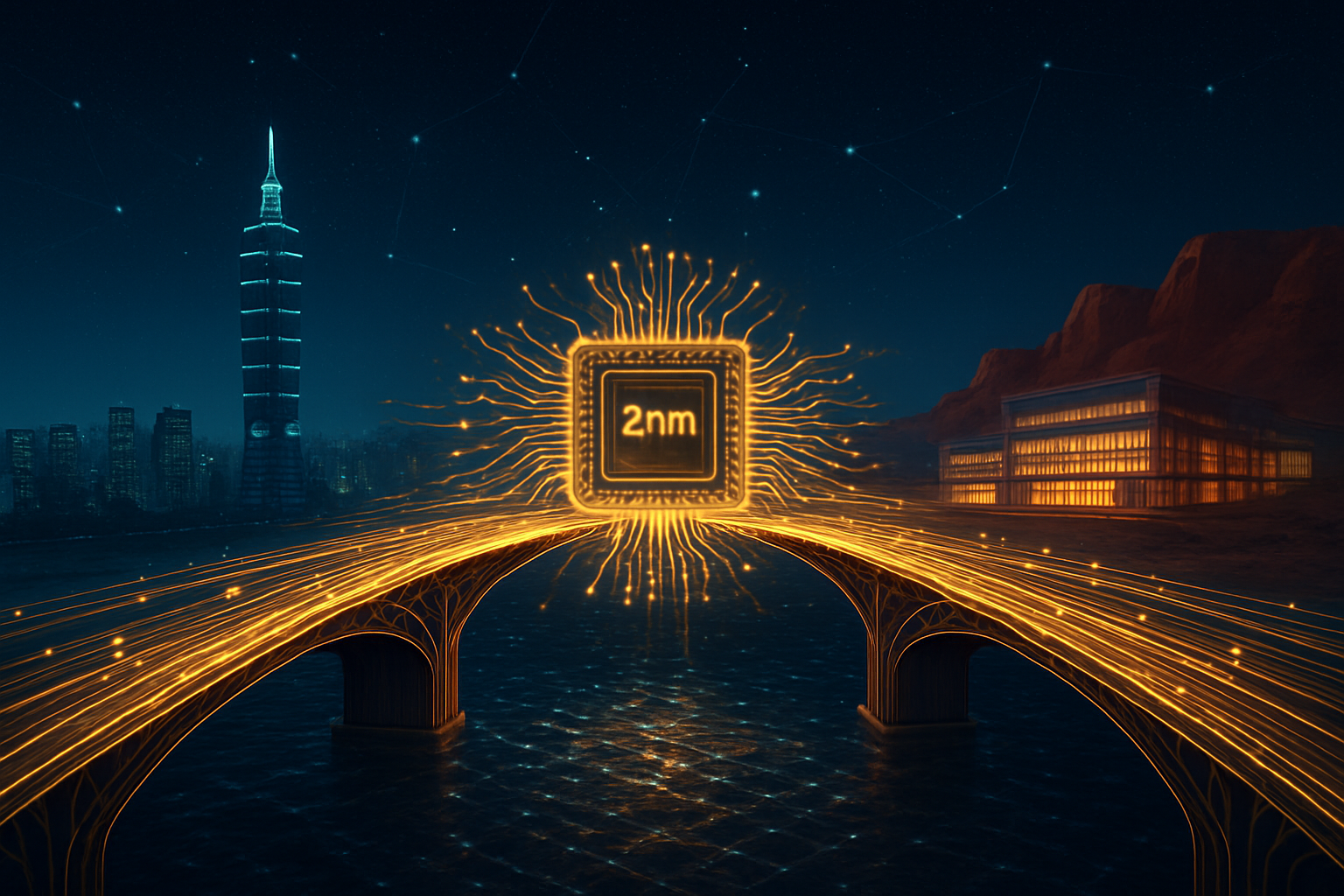

A Technical Toll Bridge: The 'U.S. Detour' Protocol

The technical crux of the new policy lies in the physical and performance-based verification of mid-to-high performance AI hardware. Under the new Bureau of Industry and Security (BIS) guidelines, chips equivalent to the Nvidia H200 and AMD MI325X—previously operating under a cloud of regulatory uncertainty—are now permitted for export to China, but only under a rigorous "detour" mandate. Every shipment must be physically routed through an independent, U.S.-headquartered laboratory. These labs must certify that the hardware’s Total Processing Performance (TPP) remains below a strict cap of 21,000, and its total DRAM bandwidth does not exceed 6,500 GB/s.

This "detour" serves two purposes: physical security and financial leverage. By requiring chips manufactured at foundries like TSMC in Taiwan to enter U.S. customs territory, the administration is able to apply a 25% Section 232 tariff on the hardware as it enters the country, and an additional "export fee" as it departs. This effectively treats the chips as a double-taxed commodity, generating an estimated $4 billion in annual revenue for the U.S. Treasury. Furthermore, the protocol mandates a "Shipment Ratio," where total exports of a specific chip model to restricted jurisdictions cannot exceed 50% of the volume sold to domestic U.S. customers, ensuring that American firms always maintain a superior compute-to-export ratio.

Industry experts and the AI research community have expressed a mix of relief and concern. While the policy provides a legal "release valve" for Nvidia to sell its H200 chips to Chinese tech giants like Alibaba (NYSE:BABA) and ByteDance, the logistical friction of a U.S. detour is unprecedented. "We are essentially seeing the creation of a technical toll bridge for the AI era," noted one senior researcher at the Center for AI Standards and Innovation (CAISI). "It provides clarity, but at the cost of immense supply chain latency and a significant 'Trump Tax' on global silicon."

Market Rerouting: Winners, Losers, and Strategic Realignment

The implications for major tech players are profound. For Nvidia and AMD, the policy is a double-edged sword. While it reopens a multi-billion dollar revenue stream from China that had been largely throttled by 2024-era bans, the 25% premium makes their products significantly more expensive than domestic Chinese alternatives. This has provided an unexpected opening for Huawei’s Ascend 910C series, which Beijing is now aggressively subsidizing to counteract the high cost of American "detour" chips. Nvidia, in particular, must now manage a "whiplash" logistics network that moves silicon from Taiwan to the U.S. for testing, and then back across the Pacific to Shenzhen.

In the cloud sector, companies like Amazon (NASDAQ:AMZN) and Microsoft (NASDAQ:MSFT) stand to benefit from the administration's "AI Action Plan," which prioritizes domestic data center hardening and provides $1.6 billion in new incentives for "high-security compute environments." However, the "Cloud Disclosure" requirement—forcing providers to list all remote end-users in restricted jurisdictions—has created a compliance nightmare for startups attempting to build global platforms. The strategic advantage has shifted toward firms that can prove a "purely American" hardware-software stack, free from the logistical and regulatory risks of the China trade.

Conversely, the market is already pricing in the risk of the July 180-day deadline. Critical mineral processors and junior mining companies in Australia, Saudi Arabia, and Canada have seen a surge in investment as they race to become the "vetted alternatives" to Chinese suppliers. Companies that fail to diversify their mineral sourcing by mid-summer 2026 face the prospect of being locked out of the U.S. market or hit with debilitating secondary tariffs.

Geopolitical Fallout and the 'Item 23' Paradigm

The broader significance of these policies lies in their departure from traditional trade diplomacy. By monetizing export controls through fees and tariffs, the administration has turned national security regulations into a tool for industrial policy. This aligns with "Item 23" of the global AI outlook: Supply Chain Trade Impacts. This paradigm shift suggests that the era of "just-in-time" globalized AI manufacturing is officially over, replaced by a "Fortress America" model that seeks to decouple the U.S. AI stack from Chinese influence at every level—from the minerals in the ground to the weights of the models.

Critics argue that this "monetized protectionism" could backfire by accelerating China’s drive for self-reliance. Beijing’s response has been to leverage its dominance in processed gallium and germanium, essentially holding the 180-day deadline over the head of the U.S. tech industry. If the U.S. cannot secure enough non-Chinese supply by July 13, 2026, the resulting shortages could spike the price of AI servers globally, potentially stalling the very "AI revolution" the administration seeks to lead. This echoes previous milestones like the 1980s semiconductor wars with Japan, but with the added complexity of a resource-starved supply chain.

Furthermore, the administration's move to strip "ideological bias" from the NIST AI Risk Management Framework marks a cultural shift in AI governance. By refocusing on technical robustness and performance over social metrics, the U.S. is signaling a preference for "objective" frontier models, a move that has been welcomed by some in the defense sector but viewed with skepticism by ethics researchers who fear a "race to the bottom" in safety standards.

The Road to July: What Happens Next?

In the near term, all eyes are on the Department of State and the USTR as they scramble to finalize "Prosperity Deals" with Saudi Arabia and Malaysia to secure alternative mineral processing hubs. These negotiations are fraught with difficulty, as these nations must weigh the benefits of U.S. partnership against the risk of alienating China, their primary trade partner. Meanwhile, the AI Overwatch Act currently moving through Congress could introduce further volatility; if passed, it would give the House a veto over individual Nvidia export licenses, potentially overriding the administration's "revenue-sharing" model.

Technologically, we expect to see a surge in R&D focused on "mineral-agnostic" hardware. Researchers are already exploring alternative substrates for high-performance computing that minimize the use of rare earth elements, though these technologies are likely years away from commercial viability. In the meantime, the "U.S. Detour" will become the standard operating procedure for the industry, with massive testing facilities currently being constructed in logistics hubs like Memphis and Dallas to handle the influx of Pacific-bound silicon.

The prediction among most industry analysts is that the July deadline will lead to a "Partial Decoupling Agreement." The U.S. is likely to secure enough supply to protect its military and critical infrastructure compute, while consumer-grade AI hardware remains subject to the volatile swings of the trade war. The ultimate challenge will be maintaining the pace of AI innovation while simultaneously rebuilding a century-old global supply chain in less than six months.

Summary of the 2026 AI Trade Landscape

The developments of January 2026 mark a definitive turning point in the history of artificial intelligence. By implementing the "U.S. Detour" protocol and setting a hard 180-day deadline for critical minerals, the Trump administration has effectively weaponized the AI supply chain. The key takeaways for the industry are clear: market access is now a paid privilege, technical specifications are subject to physical verification on U.S. soil, and mineral dependency is the primary vulnerability of the digital age.

The significance of these moves cannot be overstated. We have moved beyond "chips wars" into a "full-stack" geopolitical confrontation. As we look toward the July 13 deadline, the resilience of the U.S. AI ecosystem will be put to its ultimate test. Stakeholders should watch for the first "U.S. Detour" certifications in late February and keep a close eye on the diplomatic progress of mineral-sourcing treaties in the Middle East and Southeast Asia. The future of AI is no longer just about who has the best algorithms; it’s about who controls the dirt they are built on and the labs they pass through.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.