The artificial intelligence revolution is not merely consuming silicon; it is actively shaping its very genesis. A profound and transformative shift is underway within the semiconductor industry, where AI-powered tools and methodologies are no longer just beneficiaries of advanced chips, but rather the architects of their creation. This meta-impact of AI on its own enabling technology is dramatically accelerating every facet of semiconductor design and manufacturing, from initial chip architecture and rigorous verification to precision fabrication and exhaustive testing. The immediate significance is a paradigm shift towards unprecedented innovation cycles for AI hardware itself, promising a future of even more powerful, efficient, and specialized AI systems.

This self-reinforcing cycle is addressing the escalating complexity of modern chip designs and the insatiable demand for higher performance, energy efficiency, and reliability, particularly at advanced technological nodes like 5nm and 3nm. By automating intricate tasks, optimizing critical parameters, and unearthing insights beyond human capacity, AI is not just speeding up production; it's fundamentally reshaping the landscape of silicon development, paving the way for the next generation of intelligent machines.

The Algorithmic Architects: Deep Dive into AI's Technical Prowess in Chipmaking

The technical depth of AI's integration into semiconductor processes is nothing short of revolutionary. In the realm of Electronic Design Automation (EDA), AI-driven tools are game-changers, leveraging sophisticated machine learning algorithms, including reinforcement learning and evolutionary strategies, to explore vast design configurations at speeds far exceeding human capabilities. Companies like Synopsys (NASDAQ: SNPS) and Cadence Design Systems (NASDAQ: CDNS) are at the vanguard of this movement. Synopsys's DSO.ai, for instance, has reportedly slashed the design optimization cycle for a 5nm chip from six months to a mere six weeks—a staggering 75% reduction in time-to-market. Furthermore, Synopsys.ai Copilot streamlines chip design processes by automating tasks across the entire development lifecycle, from logic synthesis to physical design.

Beyond EDA, AI is automating repetitive and time-intensive tasks such as generating intricate layouts, performing logic synthesis, and optimizing critical circuit factors like timing, power consumption, and area (PPA). Generative AI models, trained on extensive datasets of previous successful layouts, can predict optimal circuit designs with remarkable accuracy, drastically shortening design cycles and enhancing precision. These systems can analyze power intent to achieve optimal consumption and bolster static timing analysis by predicting and mitigating timing violations more effectively than traditional methods.

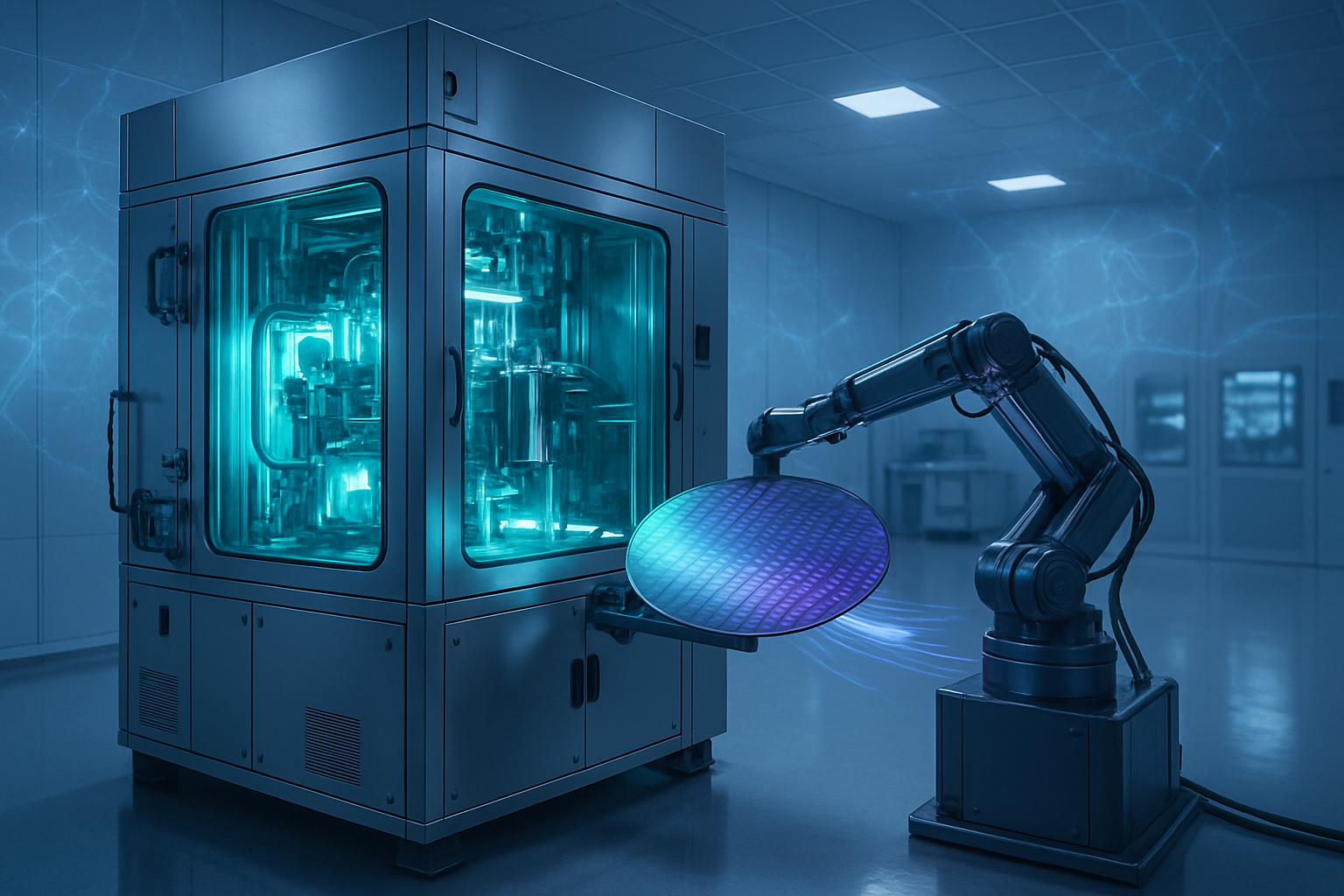

In verification and testing, AI significantly enhances chip reliability. Machine learning algorithms, trained on vast datasets of design specifications and potential failure modes, can identify weaknesses and defects in chip designs early in the process, drastically reducing the need for costly and time-consuming iterative adjustments. AI-driven simulation tools are bridging the gap between simulated and real-world scenarios, improving accuracy and reducing expensive physical prototyping. On the manufacturing floor, AI's impact is equally profound, particularly in yield optimization and quality control. Taiwan Semiconductor Manufacturing Company (TSMC) (NYSE: TSM), a global leader in chip fabrication, has reported a 20% increase in yield on its 3nm production lines after implementing AI-driven defect detection technologies. AI-powered computer vision and deep learning models enhance the speed and accuracy of detecting microscopic defects on wafers and masks, often identifying flaws invisible to traditional inspection methods.

This approach fundamentally differs from previous methodologies, which relied heavily on human expertise, manual iteration, and rule-based systems. AI’s ability to process and learn from colossal datasets, identify non-obvious correlations, and autonomously explore design spaces provides an unparalleled advantage. Initial reactions from the AI research community and industry experts are overwhelmingly positive, highlighting the unprecedented speed, efficiency, and quality improvements AI brings to chip development—a critical enabler for the next wave of AI innovation itself.

Reshaping the Silicon Economy: A New Competitive Landscape

The integration of AI into semiconductor design and manufacturing extends far beyond the confines of chip foundries and design houses; it represents a fundamental shift that reverberates across the entire technological landscape. This transformation is not merely about incremental improvements; it creates new opportunities and challenges for AI companies, established tech giants, and agile startups alike.

AI companies, particularly those at the forefront of developing and deploying advanced AI models, are direct beneficiaries. The ability to leverage AI-driven design tools allows for the creation of highly optimized, application-specific integrated circuits (ASICs) and other custom silicon that precisely meet the demanding computational requirements of their AI workloads. This translates into superior performance, lower power consumption, and greater efficiency for both AI model training and inference. Furthermore, the accelerated innovation cycles enabled by AI in chip design mean these companies can bring new AI products and services to market much faster, gaining a crucial competitive edge.

Tech giants, including Alphabet (NASDAQ: GOOGL) (Google), Amazon (NASDAQ: AMZN), Microsoft (NASDAQ: MSFT), Apple (NASDAQ: AAPL), and Meta Platforms (NASDAQ: META), are strategically investing heavily in developing their own customized semiconductors. This vertical integration, exemplified by Google's TPUs, Amazon's Inferentia and Trainium, Microsoft's Maia, and Apple's A-series and M-series chips, is driven by a clear motivation: to reduce dependence on external vendors, cut costs, and achieve perfect alignment between their hardware infrastructure and proprietary AI models. By designing their own chips, these giants can unlock unprecedented levels of performance and energy efficiency for their massive AI-driven services, such as cloud computing, search, and autonomous systems. This control over the semiconductor supply chain also provides greater resilience against geopolitical tensions and potential shortages, while differentiating their AI offerings and maintaining market leadership.

For startups, the AI-driven semiconductor boom presents a dual-edged sword. While the high costs of R&D and manufacturing pose significant barriers, many agile startups are emerging with highly specialized AI chips or innovative design/manufacturing approaches. Companies like Cerebras Systems, with its wafer-scale AI processors, Hailo and Kneron for edge AI acceleration, and Celestial AI for photonic computing, are focusing on niche AI workloads or unique architectures. Their potential for disruption is significant, particularly in areas where traditional players may be slower to adapt. However, securing substantial funding and forging strategic partnerships with larger players or foundries, such as Tenstorrent's collaboration with Japan's Leading-edge Semiconductor Technology Center, are often critical for their survival and ability to scale.

The competitive implications are reshaping industry dynamics. Nvidia's (NASDAQ: NVDA) long-standing dominance in the AI chip market, while still formidable, is facing increasing challenges from tech giants' custom silicon and aggressive moves by competitors like Advanced Micro Devices (NASDAQ: AMD), which is significantly ramping up its AI chip offerings. Electronic Design Automation (EDA) tool vendors like Synopsys (NASDAQ: SNPS) and Cadence Design Systems (NASDAQ: CDNS) are becoming even more indispensable, as their integration of AI and generative AI into their suites is crucial for optimizing design processes and reducing time-to-market. Similarly, leading foundries such as Taiwan Semiconductor Manufacturing Company (NYSE: TSM) and semiconductor equipment providers like Applied Materials (NASDAQ: AMAT) are critical enablers, with their leadership in advanced process nodes and packaging technologies being essential for the AI boom. The increasing emphasis on energy efficiency for AI chips is also creating a new battleground, where companies that can deliver high performance with reduced power consumption will gain a significant competitive advantage. This rapid evolution means that current chip architectures can become obsolete faster, putting continuous pressure on all players to innovate and adapt.

The Symbiotic Evolution: AI's Broader Impact on the Tech Ecosystem

The integration of AI into semiconductor design and manufacturing extends far beyond the confines of chip foundries and design houses; it represents a fundamental shift that reverberates across the entire technological landscape. This development is deeply intertwined with the broader AI revolution, forming a symbiotic relationship where advancements in one fuel progress in the other. As AI models grow in complexity and capability, they demand ever more powerful, efficient, and specialized hardware. Conversely, AI's ability to design and optimize this very hardware enables the creation of chips that can push the boundaries of AI itself, fostering a self-reinforcing cycle of innovation.

A significant aspect of this wider significance is the accelerated development of AI-specific chips. Graphics Processing Units (GPUs), Application-Specific Integrated Circuits (ASICs) like Google's Tensor Processing Units (TPUs), and Field-Programmable Gate Arrays (FPGAs) are all benefiting from AI-driven design, leading to processors optimized for speed, energy efficiency, and real-time data processing crucial for AI workloads. This is particularly vital for the burgeoning field of edge computing, where AI's expansion into local device processing requires specialized semiconductors that can perform sophisticated computations with low power consumption, enhancing privacy and reducing latency. As traditional transistor scaling faces physical limits, AI-driven chip design, alongside advanced packaging and novel materials, is becoming critical to continue advancing chip capabilities, effectively addressing the challenges to Moore's Law.

The economic impacts are substantial. AI's role in the semiconductor industry is projected to significantly boost economic profit, with some estimates suggesting an increase of $85-$95 billion annually by 2025. The AI chip market alone is expected to soar past $400 billion by 2027, underscoring the immense financial stakes. This translates into accelerated innovation, enhanced performance and efficiency across all technological sectors, and the ability to design increasingly complex and dense chip architectures that would be infeasible with traditional methods. AI also plays a crucial role in optimizing the intricate global semiconductor supply chain, predicting demand, managing inventory, and anticipating market shifts.

However, this transformative journey is not without its concerns. Data security and the protection of intellectual property are paramount, as AI systems process vast amounts of proprietary design and manufacturing data, making them targets for breaches and industrial espionage. The technical challenges of integrating AI systems with existing, often legacy, manufacturing infrastructures are considerable, requiring significant modifications and ensuring the accuracy, reliability, and scalability of AI models. A notable skill gap is emerging, as the shift to AI-driven processes demands a workforce with new expertise in AI and data science, raising anxieties about potential job displacement in traditional roles and the urgent need for reskilling and training programs. High implementation costs, environmental impacts from resource-intensive manufacturing, and the ethical implications of AI's potential misuse further complicate the landscape. Moreover, the concentration of advanced chip production and critical equipment in a few dominant firms, such as Nvidia (NASDAQ: NVDA) in design, TSMC (NYSE: TSM) in manufacturing, and ASML Holding (NASDAQ: ASML) in lithography equipment, raises concerns about potential monopolization and geopolitical vulnerabilities.

Comparing this current wave of AI in semiconductors to previous AI milestones highlights its distinctiveness. While early automation in the mid-20th century focused on repetitive manual tasks, and expert systems in the 1980s solved narrowly focused problems, today's AI goes far beyond. It not only optimizes existing processes but also generates novel solutions and architectures, leveraging unprecedented datasets and sophisticated machine learning, deep learning, and generative AI models. This current era, characterized by generative AI, acts as a "force multiplier" for engineering teams, enabling complex, adaptive tasks and accelerating the pace of technological advancement at a rate significantly faster than any previous milestone, fundamentally changing job markets and technological capabilities across the board.

The Road Ahead: An Autonomous and Intelligent Silicon Future

The trajectory of AI's influence on semiconductor design and manufacturing points towards an increasingly autonomous and intelligent future for silicon. In the near term, within the next one to three years, we can anticipate significant advancements in Electronic Design Automation (EDA). AI will further automate critical processes like floor planning, verification, and intellectual property (IP) discovery, with platforms such as Synopsys.ai leading the charge with full-stack, AI-driven EDA suites. This automation will empower designers to explore vast design spaces, optimizing for power, performance, and area (PPA) in ways previously impossible. Predictive maintenance, already gaining traction, will become even more pervasive, utilizing real-time sensor data to anticipate equipment failures, potentially increasing tool availability by up to 15% and reducing unplanned downtime by as much as 50%. Quality control and defect detection will see continued revolution through AI-powered computer vision and deep learning, enabling faster and more accurate inspection of wafers and chips, identifying microscopic flaws with unprecedented precision. Generative AI (GenAI) is also poised to become a staple in design, with GenAI-based design copilots offering real-time support, documentation assistance, and natural language interfaces to EDA tools, dramatically accelerating development cycles.

Looking further ahead, over the next three years and beyond, the industry is moving towards the ambitious goal of fully autonomous semiconductor manufacturing facilities, or "fabs." Here, AI, IoT, and digital twin technologies will converge, enabling machines to detect and resolve process issues with minimal human intervention. AI will also be pivotal in accelerating the discovery and validation of new semiconductor materials, essential for pushing beyond current limitations to achieve 2nm nodes and advanced 3D architectures. Novel AI-specific hardware architectures, such as brain-inspired neuromorphic chips, will become more commonplace, offering unparalleled energy efficiency for AI processing. AI will also drive more sophisticated computational lithography, enabling the creation of even smaller and more complex circuit patterns. The development of hybrid AI models, combining physics-based modeling with machine learning, promises even greater accuracy and reliability in process control, potentially realizing physics-based, AI-powered "digital twins" of entire fabs.

These advancements will unlock a myriad of potential applications across the entire semiconductor lifecycle. From automated floor planning and error log analysis in chip design to predictive maintenance and real-time quality control in manufacturing, AI will optimize every step. It will streamline supply chain management by predicting risks and optimizing inventory, accelerate research and development through materials discovery and simulation, and enhance chip reliability through advanced verification and testing.

However, this transformative journey is not without its challenges. The increasing complexity of designs at advanced nodes (7nm and below) and the skyrocketing costs of R&D and state-of-the-art fabrication facilities present significant hurdles. Maintaining high yields for increasingly intricate manufacturing processes remains a paramount concern. Data challenges, including sensitivity, fragmentation, and the need for high-quality, traceable data for AI models, must be overcome. A critical shortage of skilled workers for advanced AI and semiconductor tasks is a growing concern, alongside physical limitations like quantum tunneling and heat dissipation as transistors shrink. Validating the accuracy and explainability of AI models, especially in safety-critical applications, is crucial. Geopolitical risks, supply chain disruptions, and the environmental impact of resource-intensive manufacturing also demand careful consideration.

Despite these challenges, experts are overwhelmingly optimistic. They predict massive investment and growth, with the semiconductor market potentially reaching $1 trillion by 2030, and AI technologies alone accounting for over $150 billion in sales in 2025. Generative AI is hailed as a "game-changer" that will enable greater design complexity and free engineers to focus on higher-level innovation. This accelerated innovation will drive the development of new types of semiconductors, shifting demand from consumer devices to data centers and cloud infrastructure, fueling the need for high-performance computing (HPC) chips and custom silicon. Dominant players like Synopsys (NASDAQ: SNPS), Cadence Design Systems (NASDAQ: CDNS), Nvidia (NASDAQ: NVDA), Intel (NASDAQ: INTC), AMD (NASDAQ: AMD), Samsung Electronics (KRX: 005930), and Broadcom (NASDAQ: AVGO) are at the forefront, integrating AI into their tools, processes, and chip development. The long-term vision is clear: a future where semiconductor manufacturing is highly automated, if not fully autonomous, driven by the relentless progress of AI.

The Silicon Renaissance: A Future Forged by AI

The integration of Artificial Intelligence into semiconductor design and manufacturing is not merely an evolutionary step; it is a fundamental renaissance, reshaping every stage from initial concept to advanced fabrication. This symbiotic relationship, where AI drives the demand for more sophisticated chips while simultaneously enhancing their creation, is poised to accelerate innovation, reduce costs, and propel the industry into an unprecedented era of efficiency and capability.

The key takeaways from this transformative shift are profound. AI significantly streamlines the design process, automating complex tasks that traditionally required extensive human effort and time. Generative AI, for instance, can autonomously create chip layouts and electronic subsystems based on desired performance parameters, drastically shortening design cycles from months to days or weeks. This automation also optimizes critical parameters such as Power, Performance, and Area (PPA) with data-driven precision, often yielding superior results compared to traditional methods. In fabrication, AI plays a crucial role in improving production efficiency, reducing waste, and bolstering quality control through applications like predictive maintenance, real-time process optimization, and advanced defect detection systems. By automating tasks, optimizing processes, and improving yield rates, AI contributes to substantial cost savings across the entire semiconductor value chain, mitigating the immense expenses associated with designing advanced chips. Crucially, the advancement of AI technology necessitates the production of quicker, smaller, and more energy-efficient processors, while AI's insatiable demand for processing power fuels the need for specialized, high-performance chips, thereby driving innovation within the semiconductor sector itself. Furthermore, AI design tools help to alleviate the critical shortage of skilled engineers by automating many complex design tasks, and AI is proving invaluable in improving the energy efficiency of semiconductor fabrication processes.

AI's impact on the semiconductor industry is monumental, representing a fundamental shift rather than mere incremental improvements. It demonstrates AI's capacity to move beyond data analysis into complex engineering and creative design, directly influencing the foundational components of the digital world. This transformation is essential for companies to maintain a competitive edge in a global market characterized by rapid technological evolution and intense competition. The semiconductor market is projected to exceed $1 trillion by 2030, with AI chips alone expected to contribute hundreds of billions in sales, signaling a robust and sustained era of innovation driven by AI. This growth is further fueled by the increasing demand for specialized chips in emerging technologies like 5G, IoT, autonomous vehicles, and high-performance computing, while simultaneously democratizing chip design through cloud-based tools, making advanced capabilities accessible to smaller companies and startups.

The long-term implications of AI in semiconductors are expansive and transformative. We can anticipate the advent of fully autonomous manufacturing environments, significantly reducing labor costs and human error, and fundamentally reshaping global manufacturing strategies. Technologically, AI will pave the way for disruptive hardware architectures, including neuromorphic computing designs and chips specifically optimized for quantum computing workloads, as well as highly resilient and secure chips with advanced hardware-level security features. Furthermore, AI is expected to enhance supply chain resilience by optimizing logistics, predicting material shortages, and improving inventory operations, which is crucial in mitigating geopolitical risks and demand-supply imbalances. Beyond optimization, AI has the potential to facilitate the exploration of new materials with unique properties and the development of new markets by creating customized semiconductor offerings for diverse sectors.

As AI continues to evolve within the semiconductor landscape, several key areas warrant close attention. The increasing sophistication and adoption of Generative and Agentic AI models will further automate and optimize design, verification, and manufacturing processes, impacting productivity, time-to-market, and design quality. There will be a growing emphasis on designing specialized, low-power, high-performance chips for edge devices, moving AI processing closer to the data source to reduce latency and enhance security. The continuous development of AI compilers and model optimization techniques will be crucial to bridge the gap between hardware capabilities and software demands, ensuring efficient deployment of AI applications. Watch for continued substantial investments in data centers and semiconductor fabrication plants globally, influenced by government initiatives like the CHIPS and Science Act, and geopolitical considerations that may drive the establishment of regional manufacturing hubs. The semiconductor industry will also need to focus on upskilling and reskilling its workforce to effectively collaborate with AI tools and manage increasingly automated processes. Finally, AI's role in improving energy efficiency within manufacturing facilities and contributing to the design of more energy-efficient chips will become increasingly critical as the industry addresses its environmental footprint. The future of silicon is undeniably intelligent, and AI is its master architect.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.