As of January 2026, the global semiconductor landscape has reached a critical inflection point in the race toward the "Angstrom Era." While the industry watches the rapid evolution of artificial intelligence, Taiwan Semiconductor Manufacturing Company (TSM:NYSE) has officially entered its High-NA EUV (Extreme Ultraviolet) era, albeit with a strategy defined by characteristic caution and economic pragmatism. While competitors like Intel (INTC:NASDAQ) have aggressively integrated ASML (ASML:NASDAQ) latest high-numerical aperture machines into their production lines, TSMC is pursuing a "calculated delay," focusing on refining the technology in its R&D labs while milking the efficiency of its existing fleet for the upcoming A16 and A14 process nodes.

This strategic divergence marks one of the most significant moments in foundry history. TSMC’s decision to prioritize cost-effectiveness and yield stability over being "first to market" with High-NA hardware is a high-stakes gamble. With AI giants demanding ever-smaller, more power-efficient transistors to fuel the next generation of Large Language Models (LLMs) and autonomous systems, the world’s leading foundry is betting that its mastery of current-generation lithography and advanced packaging will maintain its dominance until the 1.4nm and 1nm nodes become the new industry standard.

Technical Foundations: The Power of 0.55 NA

The core of this transition is the ASML Twinscan EXE:5200, a marvel of engineering that represents the most significant leap in lithography in over a decade. Unlike the previous generation of Low-NA (0.33 NA) EUV machines, the High-NA system utilizes a 0.55 numerical aperture to collect more light, enabling a resolution of approximately 8nm. This allows for the printing of features nearly 1.7 times smaller than what was previously possible. For TSMC, the shift to High-NA isn't just about smaller transistors; it’s about reducing the complexity of multi-patterning—a process where a single layer is printed multiple times to achieve fine resolution—which has become increasingly prone to errors at the 2nm scale.

However, the move to High-NA introduces a significant technical hurdle: the "half-field" challenge. Because of the anamorphic optics required to achieve 0.55 NA, the exposure field of the EXE:5200 is exactly half the size of standard scanners. For massive AI chips like those produced by Nvidia (NVDA:NASDAQ), this requires "field stitching," a process where two halves of a die are printed separately and joined with sub-nanometer precision. TSMC is currently utilizing its R&D units to perfect this stitching and refine the photoresist chemistry, ensuring that when High-NA is finally deployed for high-volume manufacturing (HVM) in the late 2020s, the yield rates will meet the stringent demands of its top-tier customers.

Competitive Implications and the AI Hardware Boom

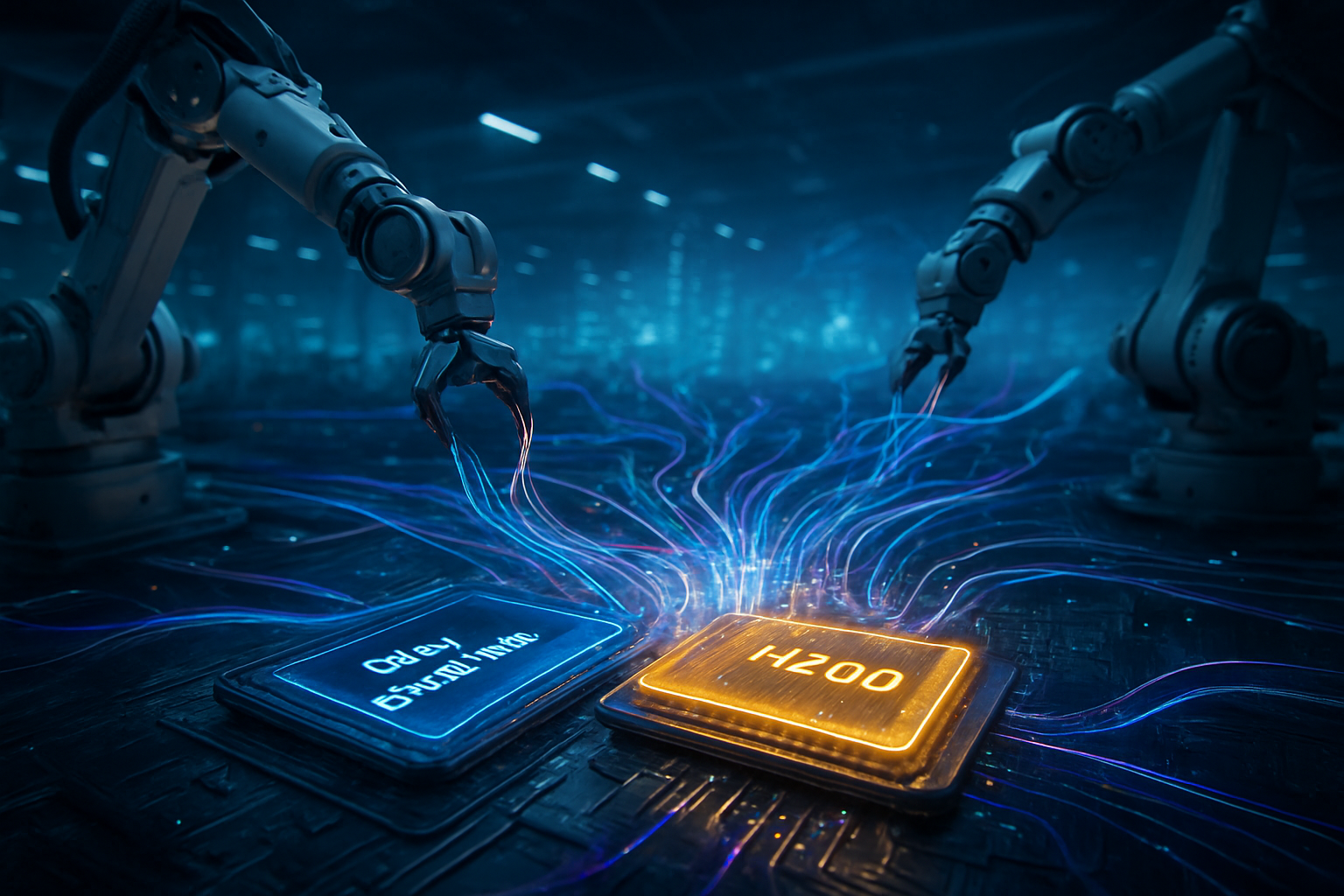

The impact of TSMC’s High-NA strategy ripples across the entire AI ecosystem. Nvidia, currently the world’s most valuable chip designer, stands as both a beneficiary and a strategic balancer in this transition. Nvidia’s upcoming "Rubin" and "Rubin Ultra" architectures, slated for late 2026 and 2027, are expected to leverage TSMC’s 2nm and 1.6nm (A16) nodes. Because these chips are physically massive, Nvidia is leaning heavily into chiplet-based designs and CoWoS-L (Chip on Wafer on Substrate) packaging to bypass the field-size limits of High-NA lithography. By sticking with TSMC’s mature Low-NA processes for now, Nvidia avoids the "bleeding edge" yield risks associated with Intel’s more aggressive High-NA roadmap.

Meanwhile, Apple (AAPL:NASDAQ) continues to be the primary driver for TSMC’s mobile-first innovations. For the upcoming A19 and A20 chips, Apple is prioritizing transistor density and battery life over the raw resolution gains of High-NA. Industry experts suggest that Apple will likely be the lead customer for TSMC’s A14P node in 2028, which is projected to be the first point of entry for High-NA EUV in consumer electronics. This cautious approach provides a strategic opening for Intel, which has finalized its 14A node using High-NA. In a notable shift, Nvidia even finalized a multi-billion dollar investment in Intel Foundry Services in late 2025 as a hedge, ensuring they have access to High-NA capacity if TSMC’s timeline slips.

The Broader Significance: Moore’s Law on Life Support

The transition to High-NA EUV is more than just a hardware upgrade; it is the "life support" for Moore’s Law in an age where AI compute demand is doubling every few months. In the broader AI landscape, the ability to pack nearly three times more transistors into the same silicon area is the only path toward the 100-trillion parameter models envisioned for the end of the decade. However, the sheer cost of this progress is staggering. With each High-NA machine costing upwards of $380 million, the barrier to entry for semiconductor manufacturing has never been higher, further consolidating power among a handful of global players.

There are also growing concerns regarding power density. As transistors shrink toward the 1nm (A10) mark, managing the thermal output of a 1000W+ AI "superchip" becomes as much a challenge as printing the chip itself. TSMC is addressing this through the implementation of Backside Power Delivery (Super PowerRail) in its A16 node, which moves power routing to the back of the wafer to reduce interference and heat. This synergy between lithography and power delivery is the new frontier of semiconductor physics, echoing the industry's shift from simple scaling to holistic system-level optimization.

Looking Ahead: The Roadmap to 1nm

The near-term future for TSMC is focused on the mass production of the A16 node in the second half of 2026. This node will serve as the bridge to the true Angstrom era, utilizing advanced Low-NA techniques to deliver performance gains without the astronomical costs of a full High-NA fleet. Looking further out, the industry expects the A14P node (circa 2028) and the A10 node (2030) to be the true "High-NA workhorses." These nodes will likely be the first to fully adopt 0.55 NA across all critical layers, enabling the next generation of sub-1nm architectures that will power the AI agents and robotics of the 2030s.

The primary challenge remaining is the economic viability of these sub-1nm processes. Experts predict that as the cost per transistor begins to level off or even rise due to the expense of High-NA, the industry will see an even greater reliance on "More than Moore" strategies. This includes 3D-stacked dies and heterogeneous integration, where only the most critical parts of a chip are made on the expensive High-NA nodes, while less sensitive components are relegated to older, cheaper processes.

A New Chapter in Silicon History

TSMC’s entry into the High-NA era, characterized by its "calculated delay," represents a masterclass in industrial strategy. By allowing Intel to bear the initial "pioneer's tax" of debugging ASML’s most complex machines, TSMC is positioning itself to enter the market with higher yields and lower costs when the technology is truly ready for prime time. This development reinforces TSMC's role as the indispensable foundation of the AI revolution, providing the silicon bedrock upon which the future of intelligence is built.

In the coming weeks and months, the industry will be watching for the first production results from TSMC’s A16 pilot lines and any further shifts in Nvidia’s foundry allocations. As we move deeper into 2026, the success of TSMC’s balanced approach will determine whether it remains the undisputed king of the foundry world or if the aggressive technological leaps of its competitors can finally close the gap. One thing is certain: the High-NA era has arrived, and the chips it produces will define the limits of human and artificial intelligence for decades to come.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.